< Workshop equipment Fume aspirators

Fume extractors are an essential component in modern machine shops, where safety and operational efficiency are top priorities. These devices are designed to remove harmful fumes generated during welding, cutting and other industrial operations, ensuring a safer working environment that complies with current regulations.

The importance of fume extractors in machine shops

In machine shops, fumes produced by various industrial processes can contain dangerous particles and chemicals that, if inhaled, can cause serious health problems. Fume extractors are designed to capture and filter these emissions, reducing workers' exposure to toxic substances. This not only improves air quality inside the workshop, but also helps comply with environmental and occupational safety regulations.

How fume extractors work

Fume extractors operate through a ventilation system that draws in contaminated air, filters it and returns it clean to the environment. The filtration process may vary depending on the type of vacuum cleaner and the specific needs of the workshop. Some models use HEPA filters to capture ultra-fine particles, while others may be equipped with activated carbon filters to eliminate odours and chemical vapours. The choice of filtration system depends on the nature of the fumes produced and local regulations.

Advantages of using fume extractors

The adoption of fume extractors in mechanical workshops offers several advantages. Firstly, it improves the health and safety of workers by reducing the risk of respiratory diseases and other conditions related to exposure to harmful substances. In addition, a cleaner and safer working environment can increase productivity, as workers are less prone to illness and absenteeism. Finally, the use of fume extractors helps companies comply with environmental regulations, avoiding penalties and improving their corporate reputation.

Types of fume extractors and their applications

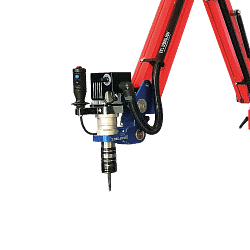

There are different types of fume extractors, each designed for specific industrial applications. Portable vacuums are ideal for welding operations in confined spaces or for work requiring mobility. Stationary vacuum cleaners, on the other hand, are more suitable for permanent installation in large workshops, where they can be connected to centralised ventilation systems. In addition, some models are equipped with flexible suction arms, which allow the vacuum cleaner to be positioned directly above the emission source, maximising the efficiency of smoke capture.

Maintenance and operation of smoke extractors

To ensure optimal operation and prolong the life of smoke extractors, regular maintenance is essential. This includes cleaning and replacing filters periodically, checking fans and motors, and inspecting seals to prevent air leaks. Proper maintenance not only ensures that the vacuum cleaner operates at peak efficiency, but also reduces the risk of breakdowns and costly downtime.

Frequently asked questions about smoke extractors

1. What are the criteria for choosing a fume extractor fan?

The choice of a fume extractor depends on various factors, including the type of fumes produced, the size of the workshop, and local regulations. It is important to consider the suction capacity, the type of filters used, and ease of maintenance.

2. Are fume extractors required by law?

In many jurisdictions, the use of fume extractors is mandatory to comply with occupational health and safety regulations. It is advisable to consult local laws to determine specific requirements.

3. How often should fume extractor filters be changed?

The frequency of filter replacement depends on the intensity of use and the type of fumes handled. In general, it is advisable to check the filters monthly and replace them when necessary to maintain the efficiency of the system.

4. Can fume extractors be used for other types of emissions?

Although primarily designed for welding and cutting fumes, some vacuum cleaners can be adapted to treat other emissions, such as dust and chemical vapours, provided they are equipped with the appropriate filters.

5. What are the costs associated with installing a fume extractor?

Costs can vary considerably depending on the type of vacuum cleaner, the size of the workshop and the specific filtration requirements. It is important to consider not only the initial purchase cost, but also the long-term maintenance and running costs.

In conclusion, fume extractors are indispensable tools for ensuring a safe and compliant working environment in machine shops. Their correct selection, installation and maintenance can have a significant impact on worker health, business productivity and regulatory compliance. Investing in a quality extraction system is a strategic decision that can bring long-term benefits to any industrial business.

Read More Read Less