< Workshop equipment Accessories for lathes

In the world of machine shops, efficiency and precision are key elements in guaranteeing quality work and customer satisfaction. Lathe accessories are a crucial element in optimising turning operations, improving productivity and the quality of the end product. In this in-depth look, we will explore in detail what lathe accessories are, what they are used for, how they are used and what advantages they offer to machine shops.

Introduction to lathe accessories

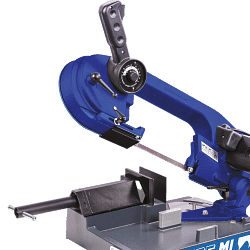

Lathe accessories are add-ons that are used to improve the functionality of a lathe, an essential machine tool in machining operations. These accessories can range from simple cutting tools to complex devices that automate and optimise the machining process. The main objective of lathe accessories is to increase the versatility and efficiency of the lathe, enabling more precise and complex machining operations.

Types of lathe accessories

There are different types of lathe accessories, each designed to meet specific needs. Among the most common are:

- Chucks: used to attach the workpiece to the lathe. They can have three or four jaws, depending on the shape and size of the workpiece.

- Tailstocks: support the workpiece, ensuring stability and precision during turning.

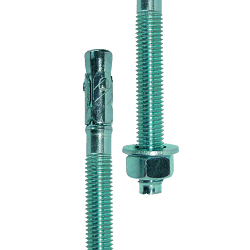

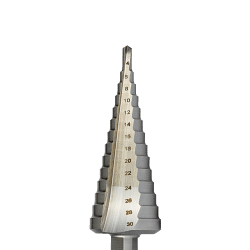

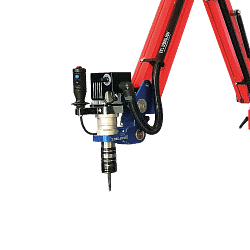

- Cutting tools: available in various shapes and materials, they are essential for carrying out cutting, drilling and threading operations.

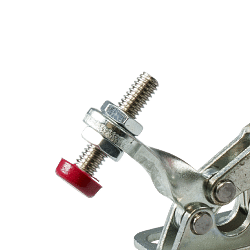

- Tool holders: devices that allow cutting tools to be quickly mounted and changed, reducing setup times.

- Automatic feed devices: they improve the efficiency of the machining process by automating the movement of the workpiece or tool.

Advantages of using lathe accessories

The adoption of lathe accessories offers numerous advantages to machine shops, including:

- Increased productivity: by enabling faster and more accurate machining, reducing machine downtime.

- Improved product quality: accessories enable better surface finishes and tighter tolerances.

- Versatility: with the use of specific accessories, a lathe can be adapted to perform a wide range of machining operations, expanding the workshop's production capabilities.

- Reduced operating costs: improved efficiency and reduced machining times contribute to lower overall production costs.

How to choose lathe accessories

The choice of lathe accessories depends on several factors, including the type of machining to be performed, the characteristics of the lathe and the specific needs of the workshop. It is important to consider:

- Compatibility: accessories must be compatible with the lathe model in use.

- Quality of materials: accessories made of high-quality materials guarantee a longer life and better performance.

- Ease of use: accessories that are easy to install and use reduce setup time and improve operating efficiency.

- Technical support: the availability of technical support and after-sales service is essential to solve any problems and ensure optimal use of the accessories.

Frequently asked questions about lathe accessories

1. What are the essential accessories for a lathe?

Essential accessories for a lathe include spindles, tailstocks, cutting tools and tool holders. These components are essential for performing basic turning operations.

2. How can I improve the precision of my lathe?

To improve the precision of your lathe, you should use high-quality accessories, such as precision spindles and tailstocks, and ensure that your lathe is properly calibrated and maintained.

3. Are lathe accessories universal?

Not all lathe accessories are universal. It is important to check the compatibility of the accessories with the specific lathe model in use.

4. What are the best materials for cutting tools?

Cutting tools can be made of various materials, including high-speed steel, tungsten carbide and ceramic. The choice of material depends on the type of machining and the material of the workpiece.

5. Is it possible to automate a lathe with accessories?

Yes, it is possible to automate a lathe using automatic feed devices and other accessories that allow machining without manual intervention.

Conclusion

Accessories for lathes are essential tools for machine shops wishing to improve the efficiency and quality of their machining operations. Choosing the right accessories can make the difference between an efficient and an inefficient production process. Investing in high-quality accessories that are compatible with your lathe is a winning strategy to guarantee excellent results and meet your customers' needs. With a wide range of accessories available on the market, workshops have the opportunity to customise and optimise their turning operations, maintaining a competitive edge in the industry.

Read More Read Less