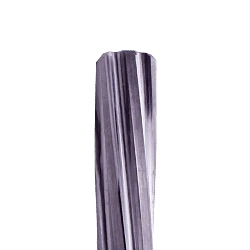

< Integral cutting tools Carbide drills

Carbide drills are a staple in the machining landscape, offering superior performance and exceptional durability compared to other materials. These tools are designed to meet the toughest challenges in machine shops, ensuring precision and efficiency in every operation. In this in-depth look, we will explore the distinctive features of carbide drills, their use in industrial applications, the advantages they offer, and answer frequently asked questions on this topic.

Characteristics of carbide drills

Carbide drills are made using a combination of tungsten carbide and cobalt, which gives them exceptional hardness and wear resistance. This composition makes them ideal for machining hard and abrasive materials, such as alloy steels, cast irons and composite materials. The carbide structure allows the drills to maintain a sharp edge for longer than with high-speed steel drills, reducing the need for frequent replacement and sharpening.

Industrial applications of carbide tips

Carbide drills are used in a wide range of industrial applications due to their ability to perform precise and fast drilling. They are particularly popular in precision machining, where tolerance and surface finish are critical. The automotive, aerospace and heavy machinery construction industries make extensive use of these drills for the production of complex, high-quality components. In addition, carbide tips are essential in deep drilling operations, where stability and heat resistance are crucial.

Advantages of carbide drills

The use of carbide drills offers several advantages over other types of drills. First of all, their superior durability translates into reduced operating costs, as they require less replacement and maintenance. In addition, the ability to maintain a sharp cutting edge allows for more precise and high-quality drilling, improving production efficiency. Carbide drills are also capable of operating at higher cutting speeds, reducing machining time and increasing overall productivity.

Proper use of carbide tips

To fully exploit the benefits of carbide tips, it is essential to use them correctly. First of all, it is important to select the right tip for the material to be machined, taking into account the technical specifications and operating conditions. In addition, it is essential to maintain proper lubrication during machining to reduce friction and heat generated, thus prolonging the life of the drill bit. Finally, it is advisable to regularly monitor the condition of the drill bits and replace them when necessary to ensure optimal performance.

Frequently asked questions about carbide drills

1. What is the difference between carbide and high-speed steel drills?

Carbide tips are harder and more wear-resistant than high-speed steel tips, which makes them ideal for working on hard, abrasive materials. However, high-speed steel drills are cheaper and may be more suitable for less demanding applications.

2. How can the service life of carbide drills be extended?

To prolong the life of carbide tips, it is important to use proper lubrication, select the right tip for the material and regularly monitor the condition of the tip to replace it when necessary.

3. Can carbide tips be used on all materials?

Although carbide tips are extremely versatile, they are not suitable for all materials. They are particularly effective on hard, abrasive materials, but may not be the best choice for softer materials, where high-speed steel tips may be more appropriate.

4. What are the recommended cutting speeds for carbide drills?

Cutting speeds for carbide tips vary depending on the material and application specifications. It is important to consult the manufacturer's recommendations and adapt the cutting speeds according to the operating conditions for best results.

5. Can carbide tips be sharpened?

Yes, carbide tips can be sharpened, but it is a process that requires specialised equipment and technical expertise. It is often more cost-effective to replace the drill rather than sharpen it, unless you have the resources to do the sharpening properly.

In conclusion, carbide drills are an excellent choice for machine shops seeking to improve the efficiency and quality of their machining operations. Thanks to their hardness and wear resistance, these tips offer superior performance and exceptional durability, making them a valuable investment for any industrial operation. With proper selection and maintenance, carbide tips can contribute significantly to the success of machining operations, ensuring high quality results and optimal productivity.

Read More Read Less