Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Free shipping in 24h from 200€

Catalogues

Customer service

How can we help you?

- Faq

- Customer service

02.927371

- Supporting big orders

02.38298620

-

info@linkindustrialtools.it

- Request assistance with form

Or contact us with the chat in the lower right corner

- Home

- Turning tools

Turning tools

The importance of turning tools in machine shops

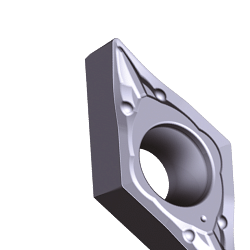

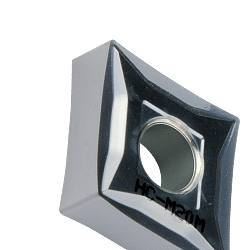

In the world of machine shops, precision and efficiency are key elements in guaranteeing the quality of the end product. Turning tools are an essential component in this context, as they enable the shaping and finishing of materials with extreme accuracy. These tools are designed to work on lathes, machine tools that rotate the workpiece while a cutting tool is applied to remove excess material. Turning is one of the most common operations in machining and requires specific tools to achieve optimum results.

What are turning tools?

Turning tools are tools used to remove material from a workpiece, giving it the desired shape. These tools are generally made of high-strength materials, such as tungsten carbides, high-speed steels or ceramics, to ensure long life and high performance. Turning tools can be classified into several categories, including external turning, internal turning, threading and grooving tools, each designed for specific applications.

Applications and uses of turning tools

Turning tools find application in a wide range of industries, including automotive, aerospace, energy and machinery manufacturing. Their versatility makes them suitable for working on various materials, such as ferrous and non-ferrous metals, alloys, plastics and composite materials. The correct use of turning tools is crucial to achieving smooth surfaces and accurate dimensions, minimising scrap and improving production efficiency.

Benefits of using turning tools

The adoption of high-quality turning tools offers numerous advantages to machine shops. First of all, these tools enable excellent surface finish, reducing the need for further finishing operations. In addition, turning tools are designed to withstand high temperatures and pressures, ensuring long tool life and reducing replacement costs. The efficiency of turning tools also translates into faster machining times, increasing the overall productivity of the workshop.

Turning tool selection: factors to consider

The selection of the most suitable turning tools depends on several factors, including the workpiece material to be machined, the desired geometry and the specifications of the lathe used. It is important to consider the hardness and strength of the material, as these will influence the choice of tool material. In addition, tool geometry, such as rake angle and cutting angle, must be optimised to ensure effective material removal and a high quality surface finish.

Maintenance and care of turning tools

To ensure optimal performance and long life of turning tools, proper maintenance practices are essential. Tools must be regularly inspected for signs of wear or damage. Cleaning tools after each use is essential to remove material residue and prevent corrosion. In addition, it is advisable to sharpen tools periodically to maintain a sharp cutting edge and ensure efficient machining.

Frequently asked questions about turning tools

1. What is the difference between external and internal turning tools?

External turning tools are designed to work on the external surface of a workpiece, while internal turning tools are used to work inside holes or cavities.

2. How can I determine the optimum cutting speed for a turning tool?

The optimum cutting speed depends on the workpiece material, the tool material and the machining conditions. It is important to consult the tool manufacturer's recommendations and conduct tests to determine the most suitable speed.

3. What are the wear signals of a turning tool?

Signs of wear include dull edges, chipping, cracks and a reduction in surface finish quality. It is important to replace or sharpen worn tools to avoid defects in the workpiece.

4. Can I use the same turning tool on different materials?

Although some tools can be used on a variety of materials, it is advisable to select specific tools for each type of material to ensure optimum performance and long tool life.

5. What are the current trends in turning tool design?

Current trends include the development of tools with advanced coatings to improve wear resistance and reduce friction, and the adoption of innovative geometries to optimise material removal and finish quality.

In conclusion, turning tools are indispensable tools in machine shops, offering precision, efficiency and versatility. The correct choice and use of these tools can significantly improve the quality of the end product and overall productivity. Investing in high-quality tools and adopting proper maintenance practices are essential steps to ensure successful turning operations.

Read More Read LessIn the world of machine shops, precision and efficiency are key elements in guaranteeing the quality of the end product. Turning tools are an essential component in this context, as they enable the shaping and finishing of materials with extreme accuracy. These tools are designed to work on lathes, machine tools that rotate the workpiece while a cutting tool is applied to remove excess material. Turning is one of the most common operations in machining and requires specific tools to achieve optimum results.

What are turning tools?

Turning tools are tools used to remove material from a workpiece, giving it the desired shape. These tools are generally made of high-strength materials, such as tungsten carbides, high-speed steels or ceramics, to ensure long life and high performance. Turning tools can be classified into several categories, including external turning, internal turning, threading and grooving tools, each designed for specific applications.

Applications and uses of turning tools

Turning tools find application in a wide range of industries, including automotive, aerospace, energy and machinery manufacturing. Their versatility makes them suitable for working on various materials, such as ferrous and non-ferrous metals, alloys, plastics and composite materials. The correct use of turning tools is crucial to achieving smooth surfaces and accurate dimensions, minimising scrap and improving production efficiency.

Benefits of using turning tools

The adoption of high-quality turning tools offers numerous advantages to machine shops. First of all, these tools enable excellent surface finish, reducing the need for further finishing operations. In addition, turning tools are designed to withstand high temperatures and pressures, ensuring long tool life and reducing replacement costs. The efficiency of turning tools also translates into faster machining times, increasing the overall productivity of the workshop.

Turning tool selection: factors to consider

The selection of the most suitable turning tools depends on several factors, including the workpiece material to be machined, the desired geometry and the specifications of the lathe used. It is important to consider the hardness and strength of the material, as these will influence the choice of tool material. In addition, tool geometry, such as rake angle and cutting angle, must be optimised to ensure effective material removal and a high quality surface finish.

Maintenance and care of turning tools

To ensure optimal performance and long life of turning tools, proper maintenance practices are essential. Tools must be regularly inspected for signs of wear or damage. Cleaning tools after each use is essential to remove material residue and prevent corrosion. In addition, it is advisable to sharpen tools periodically to maintain a sharp cutting edge and ensure efficient machining.

Frequently asked questions about turning tools

1. What is the difference between external and internal turning tools?

External turning tools are designed to work on the external surface of a workpiece, while internal turning tools are used to work inside holes or cavities.

2. How can I determine the optimum cutting speed for a turning tool?

The optimum cutting speed depends on the workpiece material, the tool material and the machining conditions. It is important to consult the tool manufacturer's recommendations and conduct tests to determine the most suitable speed.

3. What are the wear signals of a turning tool?

Signs of wear include dull edges, chipping, cracks and a reduction in surface finish quality. It is important to replace or sharpen worn tools to avoid defects in the workpiece.

4. Can I use the same turning tool on different materials?

Although some tools can be used on a variety of materials, it is advisable to select specific tools for each type of material to ensure optimum performance and long tool life.

5. What are the current trends in turning tool design?

Current trends include the development of tools with advanced coatings to improve wear resistance and reduce friction, and the adoption of innovative geometries to optimise material removal and finish quality.

In conclusion, turning tools are indispensable tools in machine shops, offering precision, efficiency and versatility. The correct choice and use of these tools can significantly improve the quality of the end product and overall productivity. Investing in high-quality tools and adopting proper maintenance practices are essential steps to ensure successful turning operations.

Most requested in the category

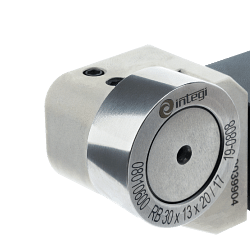

B1U20

Toolholers for external threading for positive inserts KERFOLG TURN form D - SDJCR/L As low as €74.48