< Integral cutting tools Thread milling cutters

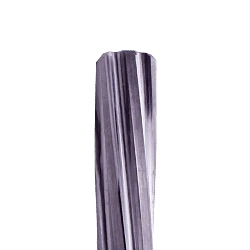

Thread milling cutters are an essential tool in modern machine shops. These tools, designed to create precise and long-lasting threads, are essential for ensuring the quality and reliability of mechanical components. In this in-depth look, we will explore in detail what thread milling cutters are, how they are used, the advantages they offer and answer some of the most frequently asked questions on this topic.

Introduction to thread milling cutters

Thread milling cutters are cutting tools used to create internal or external threads on a workpiece. Unlike males, which are mainly used for internal threads, thread milling cutters can be used for both types of threads, offering greater versatility. These tools are particularly popular in applications where high precision and a high quality surface finish are required.

How thread milling cutters work

The operating principle of thread milling cutters is based on the removal of material through a rotary and linear motion. The cutter is mounted on a machine tool, such as a CNC machining centre, and is guided along the desired path to create the thread. This process produces threads with close tolerances and an excellent surface finish, while reducing the risk of tool breakage.

Advantages of thread milling cutters

One of the main advantages of thread milling cutters is their ability to produce high-quality threads with greater efficiency than traditional methods. Due to their design, thread milling cutters can reduce machining time and improve overall productivity. They also offer greater flexibility, as they can be used for a wide range of materials, including steels, light alloys and composite materials.

Applications of thread milling cutters in machine shops

Thread milling cutters find applications in a variety of industries, including automotive, aerospace, energy and machine manufacturing. In particular, they are used for the production of critical components that require precise threads, such as screws, bolts and fittings. Their ability to work on difficult-to-cut materials makes them an ideal choice for complex and demanding applications.

How to choose the right thread milling cutter

Choosing the right thread milling cutter depends on several factors, including the material of the workpiece to be machined, the type of threading desired and the specifications of the machine tool. It is important to consider the diameter and pitch of the thread, as well as the geometry of the tool, to ensure an optimal result. In addition, the choice of tool coating can significantly influence the performance and lifetime of the cutter.

Maintenance and care of thread milling cutters

To ensure optimal performance and long life of thread milling cutters, proper maintenance practices are essential. This includes regular cleaning of tools to remove chips and machining residues, as well as periodic inspection for signs of wear or damage. In addition, it is advisable to use appropriate lubricants during the threading process to reduce friction and heat generated.

Frequently asked questions about thread milling cutters

1. What is the difference between a thread milling cutter and a male thread milling cutter?

The main difference lies in the type of thread they can create. Males are mainly used for internal threads, while thread mills can be used for both internal and external threads.

2. Can thread milling cutters be used on all materials?

Yes, thread milling cutters are designed to work on a wide range of materials, including steels, light alloys and composite materials. However, it is important to choose the right tool according to the specific material to achieve the best results.

3. What are the advantages of thread milling cutters over traditional methods?

Thread milling cutters offer greater precision, a better surface finish and greater efficiency than traditional methods. They also reduce the risk of tool breakage and can be used for a variety of applications.

4. How can I extend the service life of my thread milling cutters?

To prolong the useful life of thread milling cutters, it is important to adopt proper maintenance practices, such as regular cleaning, periodic inspection and the use of appropriate lubricants during the threading process.

5. Can thread milling cutters be used on manual machine tools?

Although thread milling cutters are primarily designed for use on CNC machine tools, they can also be used on manual machines as long as the necessary precautions are taken to ensure the accuracy and safety of the process.

Conclusion

Thread milling cutters are a crucial element in the machine shop world, offering precision, efficiency and versatility. Their ability to create high quality threads on a wide range of materials makes them indispensable for many industrial applications. With proper selection, use and maintenance, thread milling cutters can significantly improve productivity and the quality of finished products.

Read More Read Less