< Integral cutting tools Solid carbide end mills

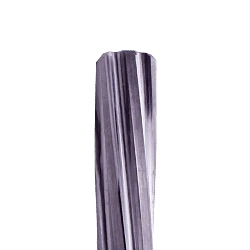

Tungsten carbide end mills represent one of the most advanced and versatile tools in the machining industry. Thanks to their unique characteristics, these tools are able to guarantee high performance and a longer tool life than other types of cutters. In this in-depth look, we will explore in detail what carbide cutters are, what they are used for, how they are used, the advantages they offer and answer some of the most frequently asked questions on this topic.

Introduction to tungsten carbide burrs

Tungsten carbide cutters are cutting tools mainly used in machining to remove material from a workpiece. Tungsten carbide, also known as cemented carbide, is a composite material consisting of tungsten carbide particles bonded together by a metal binder, usually cobalt. This combination gives tungsten carbide cutters exceptional hardness and wear resistance, making them ideal for high-speed machining and difficult-to-machine materials such as hardened steels and heat-resistant alloys.

Applications of carbide cutters

Carbide cutters are used in a wide range of industrial applications. They are particularly appreciated in machine shops for their ability to perform precise, high-quality machining. Some of the most common applications include milling flat surfaces, creating grooves, machining complex profiles and drilling holes. Due to their strength and precision, tungsten carbide milling cutters are also used in the aerospace, automotive and mould and die industries.

Advantages of tungsten carbide milling cutters

One of the main advantages of tungsten carbide end mills is their durability. Compared to high-speed steel milling cutters, carbide milling cutters can last up to ten times longer, thus reducing machine downtime and tool replacement costs. Furthermore, their ability to maintain a sharp cutting edge even at high temperatures allows them to work at higher cutting speeds, increasing productivity. The precision of tungsten carbide cutters translates into a better quality of the machined surface, reducing the need for additional finishing operations.

Correct use of carbide milling cutters

To fully exploit the advantages of carbide milling cutters, it is essential to use them correctly. First of all, it is important to select the right cutter for the material to be machined and for the specific application. Tungsten carbide cutters are available in different geometries and coatings, each of which is designed to optimise performance under certain machining conditions. In addition, it is essential to keep cutters sharp and clean to ensure long life and optimum performance. The use of appropriate lubricants during machining can help reduce wear and improve surface quality.

Frequently asked questions about tungsten carbide burrs

1. What is the difference between tungsten carbide cutters and high-speed steel cutters?

Tungsten carbide cutters are harder and more wear-resistant than high-speed steel cutters. This makes them more suitable for high-speed machining and difficult-to-machine materials. However, high-speed steel cutters can be cheaper and are often used for less demanding applications.

2. How do I choose the right tungsten carbide burr?

The choice of a tungsten carbide burr depends on the material to be machined, the type of machining and the operating conditions. It is important to consider the geometry of the cutter, the number of cutting edges, the coating and the manufacturer's specifications.

3. What are the limits of tungsten carbide burrs?

Although carbide cutters offer many advantages, they can be more fragile than other cutting tools. It is important to avoid excessive shock and vibration during machining to prevent breakage of the cutter.

4. Can tungsten carbide burrs be reground?

Yes, carbide cutters can be reground, but it is a process that requires specialised equipment and technical expertise. It is advisable to rely on professionals to ensure correct and safe regrinding.

5. What are the future trends for carbide burrs?

Innovations in the field of materials and coatings are leading to the development of increasingly advanced carbide burrs. Increased use of nanostructured coatings and additive manufacturing technologies are expected to further improve the performance and durability of the cutters.

Conclusion

Carbide cutters are an indispensable solution for machine shops seeking to optimise their machining operations. Thanks to their hardness, wear resistance and ability to work at high speeds, these cutters offer significant advantages in terms of productivity and end-product quality. However, to get the most out of these tools, it is essential to select the right cutter for the specific application and use it correctly. As technologies and materials continue to evolve, carbide cutters will continue to play a crucial role in the future of machining.

Read More Read Less