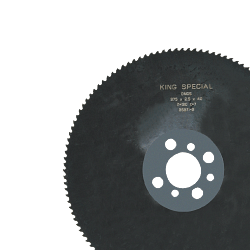

< Integral cutting tools Circular saw blades

Circular saw blades represent a key element in the panorama of machine shops, where precision and reliability are essential requirements. These tools, if chosen and used correctly, can make all the difference in terms of operational efficiency and quality of the end product. In this article, we will explore the characteristics of circular saw blades, their use, the advantages they offer and answer frequently asked questions on this topic.

Features of circular saw blades

Circular saw blades are designed to cut a wide range of materials, including wood, metal and plastic. Their structure consists of a circular disc with sharp teeth along the outer edge. Choosing the right blade depends on various factors, including the material to be cut, the desired cutting speed and the required finish. Blades can vary in terms of diameter, number of teeth, cutting angle and material of construction, such as high-speed steel or tungsten carbide.

Use of circular saw blades in machine shops

In machine shops, circular saw blades are used for precision cutting operations. These blades are mounted on circular saws, which can be manual or mounted on stationary machines. The correct use of blades requires a thorough understanding of the technical specifications and capabilities of the blade itself. It is essential to adjust the speed of the saw and the depth of cut according to the material and the blade used in order to achieve optimal results.

Advantages of circular saw blades

The use of circular saw blades offers several advantages. First of all, they guarantee precise and clean cuts, minimising the need for further machining. In addition, the high-quality blades are designed to last, reducing replacement and maintenance costs. The versatility of these blades allows them to tackle a wide range of applications, making them an indispensable tool in any machine shop.

Frequently asked questions about circular saw blades

1. What is the difference between a steel and a tungsten carbide blade?

Steel blades are generally more economical and suitable for cuts in soft wood. Tungsten carbide blades, on the other hand, are more durable and ideal for stronger materials such as metals and hardwoods.

2. How do I choose the number of teeth on a blade?

The number of teeth affects the speed and quality of the cut. Blades with more teeth offer finer and more precise cuts, while blades with fewer teeth are faster and suitable for coarse cuts.

3. How do I maintain a circular saw blade?

It is important to clean the blade regularly to remove material residues and sharpen the teeth when necessary. In addition, the blade should be stored in a dry environment to prevent corrosion.

4. What are the signs that a blade needs to be replaced?

If the blade starts to produce irregular cuts, excessive vibration or unusual noises, it may be time to replace it. The presence of damaged or worn teeth is also a clear signal for replacement.

5. Can the same blade be used for different materials?

Although some blades are designed to be multi-purpose, it is advisable to use specific blades for each type of material to ensure maximum efficiency and durability.

Conclusion

Circular saw blades are essential tools in machine shops, offering precision, efficiency and versatility. Choosing the right blade, together with proper maintenance and use, can significantly improve work quality and productivity. With a thorough understanding of their characteristics and applications, circular saw blades can become an irreplaceable ally for any professional in the industry.

Read More Read Less