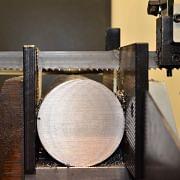

Band saw blades

Band saw blades are fundamental tools in machine shops, essential for ensuring precise, high quality cuts on a wide range of materials.

Types of Band Saw Blades

There are different types of band saw blades, each designed for specific applications. The most common are carbide blades, bimetal blades and stainless steel blades:

- Carbide blades: these are known for their durability and precision. They are particularly suitable for cutting hard, tough metals due to their high wear resistance and ability to maintain a sharp edge for a long time.

- Bimetal blades: they combine two different types of steel, offering greater flexibility and durability. These blades are ideal for industrial applications requiring intensive and continuous use.

- Stainless Steel Blades: are optimised for cutting highly resistant materials such as stainless steel. These blades ensure clean and precise cuts, reducing material waste and increasing production efficiency.

How to choose the right blade

Choosing the right blade depends on several factors, including the type of material to be cut, the precision required and the type of saw used. It is also important to consider the tooth pitch, width and thickness of the blade.

- Tooth pitch

The tooth pitch affects the speed and quality of the cut. Blades with larger teeth (low TPI - Teeth Per Inch) are ideal for faster cuts on thick materials, while smaller teeth (high TPI) are better for slower, more precise cuts on thin materials.

- Width and Thickness

Blade width determines the ability to make curved or straight cuts. Narrower blades are ideal for curved cuts, while wider blades are better for straight and precise cuts. Blade thickness affects the rigidity and durability of the blade.

Advantages of Band Saw Blades

The use of band saw blades offers numerous advantages, including:

- Cutting Precision: Band saw blades are designed to offer extremely precise cuts, minimising material waste.

- Versatility: These blades can be used on a wide range of materials, from metals to the hardest woods.

- Durability: High-quality blades, such as bimetallic blades, guarantee long life and fewer blade changes, improving production efficiency.

Frequently Asked Questions

What is the best blade for cutting hard metals?

Carbide blades are generally the best for cutting hard metals due to their high wear resistance and ability to maintain a sharp edge.

Can I use the same blade for wood and metal?

Although some bi-metal blades can be used for both materials, it is advisable to use specific blades for wood or metal for best results and longer blade life.

How to keep the blade in good condition?

To keep your blade in good condition, it is important to clean it regularly, sharpen it when necessary and follow the manufacturer's instructions for use and maintenance.

Band saw blades are essential tools in machine shops, offering precision, durability and versatility. Choosing the right blade and keeping it in good condition can make all the difference in work quality and production efficiency.