< Milling cutters Shoulder milling cutters and inserts

Milling cutters and square shoulder inserts represent essential tools in the precision machining scenario. These components are designed to ensure high efficiency and precision in milling operations, a fundamental process in the manufacture of complex mechanical components. In this in-depth look, we will explore in detail what milling cutters and inserts for straight shoulders are, how they are used, the advantages they offer and answer some of the most frequently asked questions about these tools.

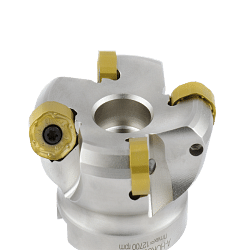

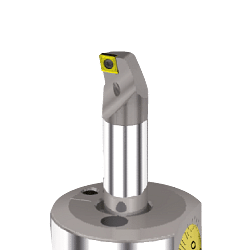

Introduction to straight shoulder burs and inserts

Right shoulder cutters are cutting tools mainly used in milling operations to create flat surfaces and right angles on a workpiece. These tools are characterised by a specific geometry that allows a 90 degree angle between the machined surface and the side surface of the workpiece. Inserts, on the other hand, are interchangeable components mounted on the cutter, designed to optimise the cutting process and improve tool life.

Operation and applications of square shoulder cutters

Square shoulder cutters are used in a wide range of industrial applications, including the production of automotive, aerospace and heavy machinery components. Their ability to create flat surfaces and precise angles makes them ideal for machining parts that require tight tolerances and high quality surface finishes. These cutters are often used in roughing and finishing operations where precision and efficiency are essential.

Advantages of using cutters and inserts for straight shoulders

The use of square shoulder cutters and inserts offers several advantages. Firstly, the ability to replace inserts reduces operating costs, as the entire cutter does not have to be replaced when the insert wears out. In addition, inserts are available in a variety of materials and geometries, allowing the cutting process to be optimised for different materials and machining conditions. This leads to greater efficiency and better quality of the end product.

Insert materials and geometries

The inserts for square shoulder cutters are made of advanced materials such as tungsten carbide, ceramic and cubic boron nitride. These materials offer excellent wear and heat resistance, allowing high performance to be maintained even under demanding machining conditions. The geometry of the inserts is designed to optimise the cutting angle and reduce cutting forces, thus improving tool life and the quality of the machined surface.

How to choose the right cutter and inserts

Choosing the right cutter and inserts depends on several factors, including the workpiece material, machining conditions and project specifications. It is important to consider cutting speed, feed rate and depth of cut to optimise tool performance. In addition, the selection of insert material and insert geometry must be made according to the characteristics of the material to be machined and surface finish requirements.

Maintenance and replacement of inserts

In order to ensure optimum performance and prolong the life of square shoulder cutters, it is essential to carry out regular maintenance and replace inserts when necessary. Inserts should be checked periodically for wear and replaced when they show signs of damage or excessive wear. Proper maintenance not only improves work quality, but also reduces downtime and operating costs.

Frequently asked questions about straight shoulder cutters and inserts

1. What is the difference between a square shoulder cutter and a conventional cutter?

Straight shoulder milling cutters are designed to create right angles and flat surfaces, whereas conventional milling cutters may have different geometries for other applications.

2. How can I improve the tool life of the inserts?

To improve the life of the inserts, it is important to choose the right material and geometry, maintain the correct cutting speed and feed rate, and perform regular maintenance.

3. What are the signs of insert wear?

Signs of insert wear include a reduction in the quality of the machined surface, increased cutting forces and tool overheating.

4. Can I use square shoulder cutters on all materials?

Right shoulder cutters can be used on a wide range of materials, but it is important to select the appropriate inserts for the specific material to be machined.

5. What are the best practices for right shoulder milling?

Best practices include selecting the right tools, maintaining optimum machining parameters and regular tool maintenance.

In conclusion, right shoulder milling cutters and inserts are indispensable tools for machine shops seeking precision and efficiency in their milling operations. With proper selection, use and maintenance, these tools can significantly improve the quality of the end product and reduce operating costs.

Read More Read Less