< Milling cutters Multifunctional milling cutters and round inserts

In the world of machine shops, efficiency and precision are key elements in guaranteeing quality work and customer satisfaction. Among the tools that play a crucial role in this context, multifunctional milling cutters and round inserts stand out for their versatility and ability to optimise production processes. These tools, in fact, represent an advanced solution for tackling a wide range of applications, from the machining of complex materials to the production of high-precision components.

The importance of multifunctional milling cutters and round inserts

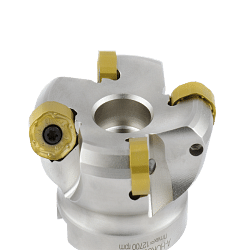

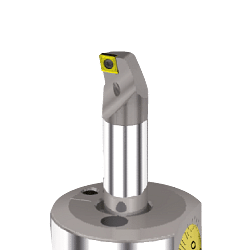

Multifunctional milling cutters are designed to perform different cutting, milling and drilling operations, reducing the need to change tools during the machining process. This not only improves operational efficiency, but also reduces machine downtime, increasing overall workshop productivity. Round inserts, on the other hand, are particularly appreciated for their ability to evenly distribute cutting forces, reducing tool wear and improving the surface finish of the workpiece.

Applications and use of multifunctional milling cutters

Multifunctional milling cutters are used in a wide range of industries, including aerospace, automotive and medical. Thanks to their ability to perform multiple operations, these cutters are ideal for machining difficult materials such as titanium alloys and stainless steels. Their versatility allows complex machining operations to be tackled with a single tool, reducing tooling costs and improving the efficiency of the production process.

Advantages of round inserts in machining

Round inserts offer numerous advantages over traditional inserts. Their shape allows an even distribution of cutting forces, reducing wear and extending tool life. In addition, round inserts are particularly effective in machining curved and complex surfaces, ensuring a high quality finish. Their ability to operate at high cutting speeds makes them ideal for high productivity applications where precision and surface quality are essential.

How to choose the right multifunctional cutters and round inserts

The choice of multi-functional cutters and round inserts depends on several factors, including the material to be machined, project specifications and the workshop's production requirements. It is important to consider tool geometry, material of construction and coating, as these elements directly influence tool performance and tool life. Working with experienced and reliable suppliers can help you select the most suitable tools for your needs, ensuring optimum results and return on investment.

Frequently asked questions about multifunctional milling cutters and round inserts

1. What are the most suitable materials for multifunctional milling cutters?

Multifunctional cutters are generally made of tungsten carbide or high-speed steel, materials that offer a good balance between hardness and wear resistance. The choice of material depends on the specific application and the materials to be machined.

2. How can the service life of round inserts be extended?

To prolong the service life of round inserts, it is essential to follow the manufacturer's recommendations in terms of cutting speed and feed rate. In addition, the use of appropriate lubricants and proper tool maintenance can help reduce wear and improve performance.

3. What are the main differences between multifunctional cutters and conventional cutters?

Multifunctional milling cutters are designed to perform several operations with a single tool, while traditional milling cutters are generally specific to one type of machining operation. This versatility makes multifunctional milling cutters more time and cost efficient.

4. Are round inserts suitable for all applications?

Round inserts are particularly suitable for applications that require an even distribution of cutting forces and a high quality surface finish. However, they may not be the best choice for all applications, particularly those requiring specific cutting geometries.

5. What are the future trends in the field of multifunctional milling cutters and round inserts?

Future trends include the development of new materials and coatings to improve tool performance, as well as the integration of advanced technologies such as CNC machining to optimise production processes.

In conclusion, multifunctional milling cutters and round inserts are essential tools for modern machine shops, offering advanced solutions to improve machining efficiency and quality. Their versatility and ability to adapt to different applications make them an ideal choice to meet the challenges of contemporary industrial production. Investing in these tools means not only improving operational performance, but also ensuring a competitive advantage in the global market.

Read More Read Less