< Measuring and precision tools Zero setters and edge finders

Setters and centring devices: essential tools for the mechanical industry

In the mechanical industry, precision is a crucial element that determines the quality and efficiency of production processes. Zero-setters and centring devices are essential tools that help to ensure this precision, enabling optimum results in terms of component alignment and positioning. In this article, we will explore in detail what zeroers and centring devices are, what they are used for, how they are used and what advantages they offer. We will also answer some of the most frequently asked questions about these indispensable tools.

Understanding zeroers and centrators

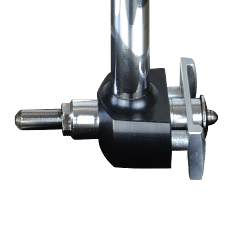

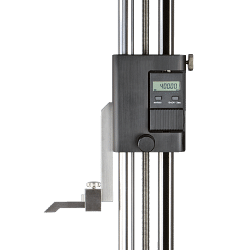

Setters and centring devices are devices used primarily in machine shops to ensure the precise alignment of workpieces during machining operations. Zero setters, as their name suggests, are tools that allow a 'zero' reference point to be set on a machine tool. This reference point is essential to ensure that all subsequent measurements and machining operations are accurate and consistent.

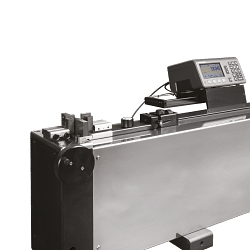

Centring devices, on the other hand, are used to position a workpiece correctly with respect to the tool or machine. They ensure that the workpiece is optimally aligned, minimising machining errors and improving the quality of the final product.

The importance of precision in machining

Precision is a crucial factor in machining, as it directly affects the quality and reliability of the components produced. Incorrect alignment can lead to defects in parts, compromising their functionality and durability. Setters and centring devices play a crucial role in preventing such errors, ensuring that every machining operation is performed with the utmost accuracy.

How to use zeroers and centring devices

The correct use of zeroers and centring devices requires a thorough understanding of their functions and application techniques. Zero setters are generally mounted on the machine tool and used to set the zero reference point. This process may vary depending on the type of machine and the specific application, but in general, the zeroiser is positioned so that its sensor touches the surface of the workpiece, thus determining the zero point.

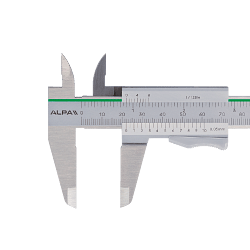

Centring devices, on the other hand, are used to position the workpiece. This can be done manually or with the aid of advanced measuring instruments such as dial gauges or calipers. The aim is to ensure that the workpiece is perfectly aligned with the tool, minimising machining errors.

Advantages of using zeroers and centring devices

The adoption of datum setters and centring devices in machining operations offers numerous advantages. Firstly, they improve the precision and accuracy of machining operations, minimising errors and defects in the parts produced. This translates into higher quality of the final product and a reduction in costs associated with rework and scrap.

In addition, the use of these tools contributes to optimising machining times, as it allows machining parameters to be set quickly and accurately. This results in greater production efficiency and better utilisation of available resources.

Frequently asked questions about zero-setters and centring devices

1. What types of zero-setters are available on the market?

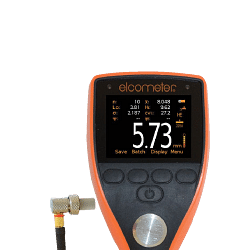

There are different types of zero-setters, including mechanical, electronic and optical. The choice of the type of zeroiser depends on the specific needs of the application and the level of accuracy required.

2. How do I choose the right zero-setter for my application?

The choice of the datum setter depends on various factors, including the type of machine tool, the material of the part and the level of accuracy required. It is also important to consider ease of use and compatibility with other measuring instruments.

3. What are the best practices for keeping zero-setters and centring devices in good condition?

To ensure the longevity and efficiency of zeroers and centrators, regular maintenance is essential. This includes cleaning the instruments, checking their calibration and replacing worn parts.

4. Can zeroers and centring devices be used on all machine tools?

Although zeroers and centring devices are versatile tools, it is important to check compatibility with the specific machine tool. Some models may require adaptations or additional accessories to function properly.

5. What are the recent innovations in the field of zero-setters and centring tools?

In recent years, several innovations have been introduced in the field of zero-setters and centring devices, including the integration of digital technologies and advanced sensors. These innovations improve the accuracy and efficiency of the instruments, making them even more indispensable for modern machine shops.

Conclusions

Zero-setters and centring tools are essential tools for precision and efficiency in machining operations. Their correct application allows high quality results to be obtained, minimising errors and optimising production times. With the evolution of technologies and the introduction of new solutions, these tools continue to represent a fundamental pillar for the mechanical industry, contributing to the continuous improvement of production processes and the satisfaction of customer needs.

Read More Read Less