< Measuring and precision tools Thickness and adhesion gauges

Thickness and adhesion gauges are essential tools in the context of machine shops, where accuracy and reliability are crucial to ensure the quality of finished products. These devices are designed to accurately measure the thickness of materials and coatings, as well as to assess the adhesion of paints and other surface coatings. In this in-depth look, we will explore in detail what thickness and adhesion gauges are, how they work, their benefits and practical applications in machine shops.

Understanding Thickness and Adhesion Gauges

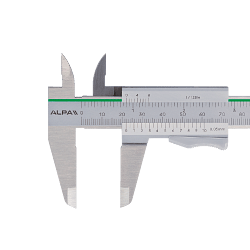

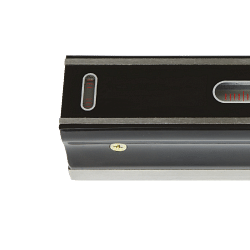

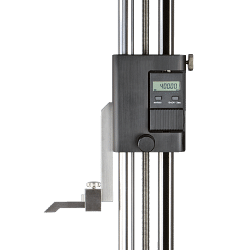

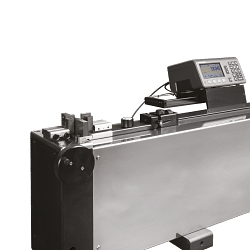

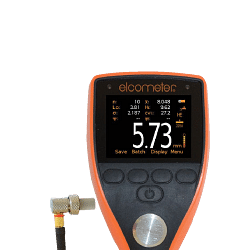

Thickness gauges are instruments used to determine the thickness of a material or coating. These devices can be based on different technologies, including ultrasound, magnetism and eddy current. Ultrasound, for example, is particularly useful for measuring the thickness of non-metallic materials, while magnetic gauges are ideal for coatings on metallic substrates.

On the other hand, adhesion meters are designed to assess the strength with which a coating adheres to a surface. This is crucial to ensure that coatings do not peel off or deteriorate prematurely, compromising product integrity.

Practical applications in machine shops

In machine shops, thickness and adhesion gauges find application in a wide range of processes. For example, in the production of automotive components, it is essential to ensure that protective coatings are applied at the correct thickness to prevent corrosion. Similarly, in the aerospace industry, accuracy in measuring the thickness of composite materials is crucial for the safety and efficiency of aircraft.

Benefits of using thickness and adhesion gauges

The adoption of thickness and adhesion gauges offers numerous advantages. Firstly, these instruments improve the quality of the final product by ensuring that coatings are applied correctly and that materials meet the required specifications. Furthermore, the use of these devices can reduce production costs by minimising waste and preventing the need for costly rework.

Technologies behind thickness gauges

Thickness gauges can be divided into different categories according to the technology used. Ultrasonic gauges, for example, emit sound waves that pass through the material and measure the time it takes to reflect, thus calculating the thickness. Magnetic gauges, on the other hand, use magnetic fields to determine the thickness of coatings on metal substrates. Finally, eddy current meters are ideal for measuring non-conductive coatings on metallic substrates.

How to choose the right gauge for your needs

The choice of the most suitable thickness or adhesion meter depends on several factors, including the type of material to be measured, the thickness of the coating and the working environment. It is also important to consider the required accuracy and ease of use of the instrument. Investing in a high-quality gauge can make all the difference in terms of efficiency and reliability of the production process.

Frequently asked questions about thickness and adhesion gauges

1. What is the difference between an ultrasonic thickness gauge and a magnetic gauge?

- Ultrasonic gauges are ideal for non-metallic materials, while magnetic gauges are designed for coatings on metallic substrates.

2. How do I calibrate a thickness gauge?

- Calibration of a thickness gauge varies depending on the model, but generally requires the use of known reference standards to ensure accurate measurements.

3. Why is it important to measure the adhesion of a coating?

- Measuring adhesion is crucial to ensure that the coating does not peel off, compromising the protection and aesthetics of the product.

4. What are the most common applications of adhesion meters?

- Adhesion meters are commonly used in the automotive, aerospace and white goods industries to ensure the quality of coatings.

5. What are the advantages of using digital versus analogue gauges?

- Digital gauges offer greater accuracy, ease of use and the possibility of storing and analysing the collected data.

Conclusions

Thickness and adhesion gauges are indispensable tools in modern machine shops. Their ability to guarantee the quality and reliability of finished products makes them an essential investment for any company wishing to maintain high production standards. Choosing the right gauge and using it correctly can lead to significant improvements in efficiency, cost reduction and customer satisfaction.

Read More Read Less