< Measuring and precision tools Snap gauges

Dial gauges with probe arms are an essential tool in the modern machine shop environment. These devices, known for their precision and reliability, are designed to measure and verify the dimensions of mechanical components with a level of accuracy that few other tools can match. In this in-depth look, we will explore in detail what dial gauges with probe arms are, how they work, their advantages and practical applications in industry.

Understanding dial gauges with touch probes

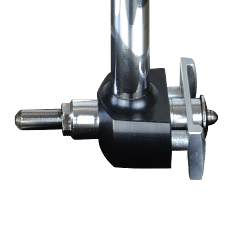

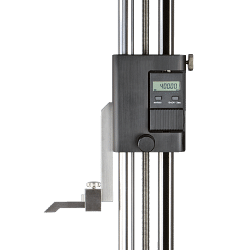

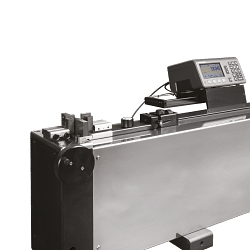

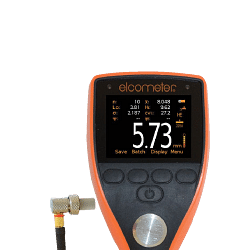

Dial gauges with probe arms are measuring instruments that use a moving arm fitted with a probe to detect dimensional changes in an object. The probe, which can be either contact or non-contact, moves along the surface of the workpiece, recording deviations from a predefined reference value. These deviations are then displayed on a dial or digital display, allowing the operator to accurately assess the dimensions of the component.

Operation and technology behind it

The operating principle of dial gauges with probe arms is based on the mechanical transduction of dimensional variations into readable signals. The probe arm, often made of strong, lightweight materials such as carbon or aluminium, is connected to a transmission system that amplifies the movement of the probe. This movement is then converted into an electrical or mechanical signal that is displayed on the reading device. The advanced technology of these instruments makes it possible to obtain measurements with an accuracy of up to a few microns.

Advantages of using dial gauges with probe arms

The adoption of dial gauges with probe arms in machine shops offers numerous advantages. First of all, the accuracy of the measurements makes it possible to guarantee the quality of the components produced, minimising rejects and defects. In addition, the speed at which measurements can be taken allows production times to be optimised, increasing operational efficiency. Another significant advantage is the versatility of these instruments, which can be used to measure a wide range of components, from the smallest to the largest, thanks to the possibility of adjusting the length of the probe arm.

Practical applications in industrial sectors

Dial gauges with probe arms find application in a variety of industries, including automotive, aerospace, and machinery manufacturing. In the automotive industry, for example, they are used to check the accuracy of engine and transmission parts, ensuring that each component meets the required specifications. In the aerospace industry, the need for precision is even more critical, and touch-trigger gauges are used to check tolerances on aircraft structural parts. In machine manufacturing, these instruments are also essential to ensure that mechanical parts fit together perfectly, avoiding assembly and operational problems.

Frequently asked questions about dial gauges with probe arms

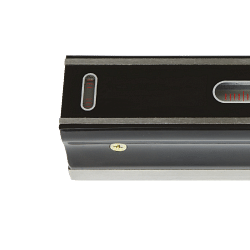

One of the most common questions concerns the calibration of dial gauges with probe arms. It is essential that these instruments are calibrated regularly to maintain their accuracy. Calibration can be carried out in-house, if the workshop has the necessary equipment, or outsourced to a specialised external service.

Another frequent question concerns maintenance. Comparators with probe arms require minimal maintenance, but it is important to ensure that the probe is always clean and free of debris that could affect measurements. It is also advisable to periodically check the integrity of the probe arm and transmission system to prevent any malfunctions.

Conclusions

Touch probes are indispensable tools for machine shops that strive for quality and efficiency. Their ability to provide accurate and reliable measurements makes them a valuable investment for any company wishing to maintain high production standards. With proper calibration and maintenance, these instruments can provide years of reliable service, contributing to a company's success and competitiveness in the global marketplace.

Read More Read Less