< Measuring and precision tools Roughness testers

Roughness gauges are essential tools in machine shops and manufacturing industries, where precision and surface quality are of paramount importance. These devices are designed to measure surface roughness, a critical parameter that affects the performance, wear and aesthetics of mechanical components. In this in-depth look, we will explore in detail what roughness gauges are, how they work, their benefits and practical applications in industry.

Understanding Roughness Gauges: A Technical Overview

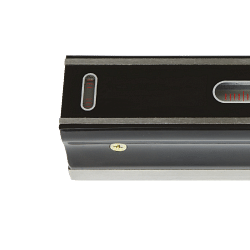

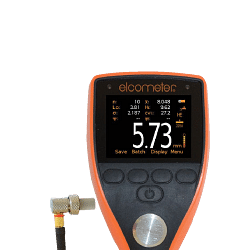

Roughness gauges are measuring instruments that quantify the roughness of a surface, expressed in terms of parameters such as Ra (arithmetic mean roughness), Rz (mean height of irregularities) and others. These parameters are crucial in determining the quality of the surface finish, which in turn can influence friction, wear resistance and the adhesion ability of coatings or lubricants.

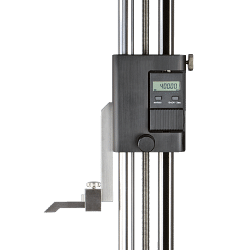

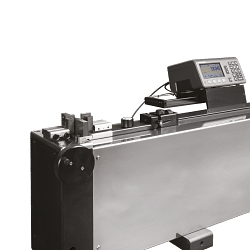

Roughness gauges can be either contact or non-contact types. Contact types use a stylus that slides over the surface, while non-contact types employ optical or laser technology to detect irregularities. The choice between the two depends on the specific application requirements, such as the delicacy of the surface or the required measuring speed.

The importance of roughness in industrial applications

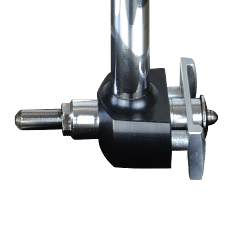

The roughness of a surface can significantly influence the performance of a mechanical component. For example, in a bearing system, a surface that is too rough can increase friction and wear, reducing component life. Conversely, a surface that is too smooth may not adequately retain lubricant, leading to premature wear.

In addition, roughness can affect the aesthetics and functionality of finished products. In the automotive and aerospace industries, for example, a high-quality surface finish is essential not only for aesthetic reasons, but also to improve aerodynamics and reduce fuel consumption.

How to use roughness gauges in machine shops

The correct use of roughness testers requires a thorough understanding of measurement techniques and device specifications. Before starting a measurement, it is essential to calibrate the roughness tester to the appropriate standards to ensure accurate results. Calibration may vary depending on the type of roughness tester and the surface material to be measured.

During measurement, it is important to keep the roughness tester stable and follow the manufacturer's guidelines to avoid errors. Environmental conditions, such as temperature and humidity, can affect readings, so it is advisable to perform measurements in a controlled environment.

Advantages of using rugosimeters

There are several advantages to using roughness gauges in machine shops. First of all, it allows compliance with quality standards to be guaranteed, reducing the risk of defects in finished products. In addition, roughness analysis can help optimise production processes by identifying areas where surface finish can be improved.

The use of roughness testers can also help reduce operating costs. By identifying and correcting rough surfaces before they cause problems, companies can avoid costly repairs and component replacements. In addition, a better surface finish can improve the energy efficiency of machinery, reducing energy consumption.

Frequently Asked Questions about Roughness Gauges

1. What is the difference between roughness and waviness?

Roughness refers to small irregularities on the surface, whereas waviness concerns larger, spaced-out variations. Both parameters are important for surface quality, but are measured and analysed separately.

2. How do I choose the right roughness tester for a specific application?

The choice of a roughness tester depends on several factors, including the type of surface, the required accuracy and the available budget. It is advisable to consult an expert or the manufacturer to determine the most suitable model for your needs.

3. Do roughness testers require maintenance?

Yes, roughness testers require regular maintenance to ensure optimal performance. This includes cleaning the stylus or lens, periodic calibration and checking the operating conditions.

Conclusions

Roughness gauges are indispensable tools for machine shops and industries that strive for quality and efficiency. Understanding how they work and how to use them correctly can make the difference between a successful product and one that does not meet market standards. Investing in a quality rugosimeter and training staff in its correct use can lead to significant improvements in production processes and business results.

Read More Read Less