In the world of machine shops, precision and accuracy are key elements in ensuring the quality of the work performed. Optical instruments such as microscopes, lenses and viewers play a crucial role in this context, allowing operators to examine microscopic details and perform quality checks with a level of precision that would otherwise be unattainable. In this in-depth look, we will explore the features, applications and benefits of these instruments, providing a comprehensive overview for those working in industry.

The importance of microscopes in machine shops

Microscopes are optical instruments that enable small objects to be enlarged, making visible details otherwise invisible to the naked eye. In machine shops, microscopes are mainly used for inspection and quality control of mechanical components. Due to their magnification capability, microscopes allow the detection of manufacturing defects, micro-fractures and other imperfections that could compromise the functionality of machined parts.

There are different types of microscopes used in industry, including optical, electronic and digital microscopes. Optical microscopes are the most common and use lenses to magnify the image of the object being observed. Electron microscopes, on the other hand, use a beam of electrons to obtain very high resolution images, ideal for analysing surfaces and materials. Finally, digital microscopes combine traditional optics with digital technology, allowing images to be viewed and analysed on a computer.

Lenses: precision instruments for detailed analysis

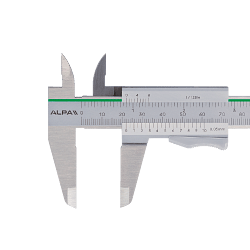

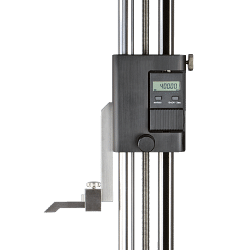

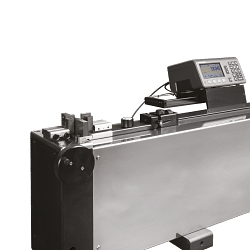

Lenses are fundamental optical components that are used in a wide range of instruments and devices. In machine shops, lenses are used in various measuring and inspection instruments, such as optical gauges and profile projectors. These instruments allow precise measurements to be taken and component profiles to be compared with technical drawings, ensuring that specifications are met.

Lenses can be made of different materials, including glass and plastic, and can have different shapes and curvatures depending on the specific application. The quality of the lenses is determined by their ability to focus light without distortion, a crucial aspect in ensuring accurate measurements.

Visors: technology in the service of safety and efficiency

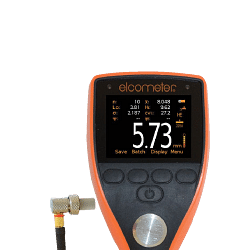

Visors are optical devices that allow images or data to be displayed clearly and in detail. In machine shops, viewers are often used to improve the safety and efficiency of operations. For example, augmented reality displays can superimpose digital information onto the operator's field of view, providing real-time instructions and reducing the risk of errors.

In addition, visors can be used for visual inspection of components and assemblies, allowing operators to detect defects and anomalies without having to interrupt the production process. This ability to perform real-time inspections helps to improve the quality of the final product and reduce machine downtime.

Benefits of using optical instruments in machine shops

The integration of microscopes, lenses and viewers in machine shops offers numerous advantages. First of all, these instruments improve the precision and accuracy of operations, allowing the tightest tolerances to be met and guaranteeing the quality of manufactured components. Furthermore, the use of optical instruments reduces inspection and control time, increasing the overall efficiency of the production process.

Another significant advantage is the possibility of documenting and analysing inspection results in detail. Digital microscopes, for example, allow images and data to be saved for later analysis, facilitating traceability and quality management. Finally, the adoption of augmented reality displays and other advanced technologies helps to improve operator safety, reducing the risk of accidents and improving the ergonomics of workstations.

Frequently asked questions on the use of optical tools in machine shops

1. What are the main criteria to consider when choosing a microscope for a machine shop?

The choice of a microscope depends on several factors, including the type of analysis to be performed, the level of magnification required and the budget available. It is also important to consider ease of use and compatibility with other instruments and software used in the workshop.

2. How are the lenses used in measuring instruments maintained in good condition?

Lens maintenance is essential to ensure accurate measurements. It is advisable to clean the lenses regularly with soft cloths and specific solutions, avoiding the use of abrasive materials that could scratch the surface.

3. What are the most common applications of augmented reality displays in machine shops?

Augmented reality displays are used to provide assembly instructions, visualise schematics and technical drawings, and for visual inspection of components. These devices improve efficiency and reduce the risk of errors during operations.

4. What are the advantages of digital microscopes over traditional microscopes?

Digital microscopes offer the possibility of viewing and analysing images on a computer, facilitating the documentation and sharing of results. In addition, they allow more detailed measurements and analysis thanks to advanced software.

5. How does the use of optical instruments affect the quality of the final product?

The use of optical instruments improves the precision and accuracy of operations, allowing defects and anomalies to be detected and corrected before components are assembled or shipped. This helps to guarantee the quality of the final product and reduce production costs.

In conclusion, the adoption of microscopes, lenses and viewers in machine shops is a strategic investment to improve the quality and efficiency of operations. These tools provide indispensable support for inspection and quality control, helping to ensure compliance with specifications and reduce downtime. As optical technologies continue to evolve, machine shops can benefit from increasingly advanced and customised solutions to meet the specific needs of the industry.

Read More Read Less