< Measuring and precision tools Digital micrometers

Digital micrometers are an essential tool for modern machine shops, where the accuracy and reliability of measurements are crucial to ensure the quality of finished products. These advanced measuring instruments offer a number of advantages over traditional analogue micrometers, making them a preferred choice for many professionals.

Introduction to digital micrometers

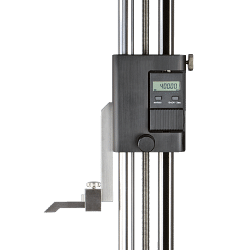

Digital micrometers are measuring devices used to accurately determine the dimensions of an object. Unlike traditional micrometers, which require the manual reading of a graduated scale, digital micrometers provide a direct reading on a digital display. This not only reduces the margin of human error, but also speeds up the measurement process, making it more efficient.

Operation and use of digital micrometers

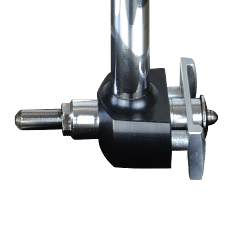

The operation of a digital micrometer is based on a system of transducers that convert mechanical movement into an electrical signal, which is then displayed as a digital measurement. This system allows extremely precise measurements to be obtained, often with a resolution down to 0.001 mm. The use of a digital micrometer is relatively simple: the object to be measured is placed between the anvil and the spindle of the micrometer, and the spindle is brought close to the object until it lightly touches it. At this point, the digital display will show the exact measurement.

Advantages of digital micrometers in machine shops

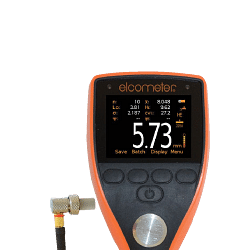

One of the main advantages of digital micrometers is their accuracy. In a sector such as machine shops, where even the slightest inaccuracy can compromise the quality of the end product, the ability to obtain accurate measurements is crucial. Furthermore, digital micrometers offer greater ease of use than analogue models, reducing the time needed for measurements and minimising the risk of human error.

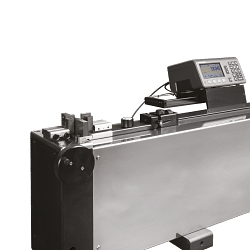

Another significant advantage is the possibility of storing and transferring measurement data. Many digital micrometers have the capability to connect to computers or other devices, allowing measurements to be automatically recorded for later analysis. This is particularly useful in production environments where the quality and conformity of products must be constantly monitored.

Practical applications of digital micrometers

Digital micrometers find application in a wide range of industries. In machine shops, they are used to measure components such as shafts, gears and bearings, where accuracy is essential to ensure the proper functioning of machines. They are also used in quality control to verify that finished products meet the required dimensional specifications.

In the aerospace industry, digital micrometers are used to measure critical components that require extremely tight tolerances. In the automotive industry, these instruments are also essential to ensure that engine and chassis components are manufactured with precision.

Frequently asked questions about digital micrometers

1. What is the difference between a digital and an analogue micrometer?

The main difference lies in the reading method. Digital micrometers provide a direct reading on a display, whereas analogue micrometers require a graduated scale to be read. Digital micrometers tend to be more accurate and easier to use.

2. How do you calibrate a digital micrometer?

Calibrating a digital micrometer is essential to ensure accurate measurements. This process usually involves using precision calibration blocks and adjusting the micrometer to align the digital reading with the known block size.

3. What are the features to consider when buying a digital micrometer?

When choosing a digital micrometer, it is important to consider resolution, accuracy, ease of use and additional features such as the ability to store and transfer data. The instrument's robustness and durability are also important factors, especially in demanding work environments.

Conclusion

Digital micrometers are a valuable investment for machine shops and other industries that require accurate and reliable measurements. Their ability to provide accurate readings, reduce the risk of human error and improve the efficiency of the measurement process makes them an indispensable tool for ensuring product quality and conformity. As technology continues to evolve, digital micrometers will continue to improve, offering ever more advanced functionality to meet the ever-growing needs of modern industry.

Read More Read Less