< Measuring and precision tools Digital gauges

Digital dial gauges are an essential component in modern machine shops, where precision and efficiency are crucial to ensure product quality and customer satisfaction. These advanced instruments are designed to measure the physical dimensions of an object with extreme accuracy, allowing operators to detect even the smallest deviations from design specifications. In this in-depth look, we will explore in detail what digital dial gauges are, how they work, their benefits and practical applications in machine shops.

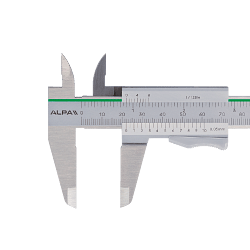

Understanding digital dial gauges

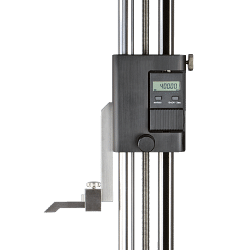

Digital dial gauges are measuring instruments that use a digital display to show measurement readings. Unlike analogue dial gauges, which require a visual dial readout, digital dial gauges offer superior accuracy and ease of use due to their ability to provide direct and easily interpretable readings. These instruments are equipped with an electronic sensor that detects the movement of a piston or measuring rod, converting this movement into an electrical signal that is then shown on the display.

Operation and use of digital dial gauges

The operation of a digital dial indicator is based on a simple but effective principle: measuring the distance travelled by a piston or measuring rod. When the rod is moved, the electronic sensor detects the movement and translates it into a numerical value that appears on the display. This process results in extremely precise measurements, with a resolution of up to 0.001 millimetres.

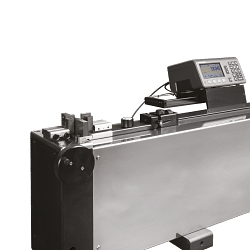

The use of digital dial gauges in machine shops is varied and includes checking dimensional tolerances, checking the quality of machined parts and calibrating other measuring instruments. Due to their accuracy, digital dial gauges are particularly useful in applications where even the slightest deviation can compromise the functionality of a component.

Benefits of digital dial gauges in machine shops

The adoption of digital dial gauges in machine shops offers several advantages. Firstly, the accuracy of the measurements minimises production waste, improving efficiency and reducing costs. Furthermore, the ease of use of digital dial gauges reduces the margin for human error, as readings are clear and direct.

Another significant advantage is the possibility of storing and transferring measurement data. Many digital dial gauges are equipped with connectivity features that allow the instrument to be connected to a computer or quality management system, facilitating data analysis and measurement traceability.

Practical applications of digital dial gauges

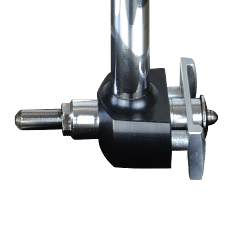

In machine shops, digital dial gauges find application in a wide range of processes. They are used for the dimensional control of mechanical components, such as shafts, gears and bearings, where accuracy is crucial to ensure the correct functioning of the end product. They are also used in the calibration of machine tools, ensuring that equipment is always in optimum condition for production.

Digital dial gauges are also essential in quality control, where they are used to verify that finished products meet design specifications. This is especially important in industries such as automotive and aerospace, where component safety and reliability are paramount.

Frequently asked questions about digital dial gauges

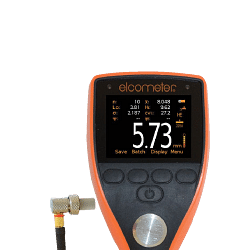

One of the most common questions about digital dial gauges relates to their calibration. It is essential to calibrate these instruments regularly to ensure measurement accuracy. Calibration can be done in-house, using certified calibration blocks, or externally, using specialised laboratories.

Another frequent question concerns the maintenance of digital dial gauges. Although these instruments are designed to be robust and durable, it is important to keep them clean and protected from dust and moisture to preserve their functionality. In addition, it is advisable to periodically check the batteries and replace them when necessary to avoid interruptions during use.

Conclusions

Digital dial gauges are indispensable tools in modern machine shops, offering precision, efficiency and ease of use. Their ability to provide accurate measurements and support quality control makes them an ideal choice for companies aiming to improve their production and ensure customer satisfaction. With proper calibration and maintenance, digital dial gauges can offer reliable and long-lasting performance, contributing to the success of mechanical operations.

Read More Read Less