< Measuring and precision tools Digital and analogue hardness testers

In the world of machine shops, precision is a crucial element that determines the quality and reliability of finished products. Among the instruments that are essential to ensure such precision, digital and analogue hardness testers occupy a prominent place. These instruments are essential for measuring the hardness of materials, a parameter that directly affects the performance and durability of mechanical components. In this in-depth look, we will explore in detail what hardness testers are, how they work, their benefits and practical applications in machine shops.

Understanding hardness testers: precision instruments for measuring hardness

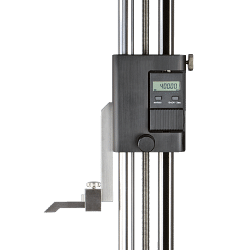

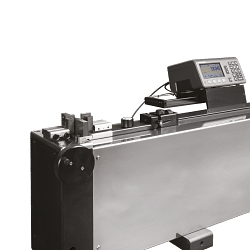

Hardness testers are instruments designed to measure the hardness of a material, which is the material's resistance to permanent deformation. There are two main types of hardness testers: digital and analogue. Digital hardness testers use an electronic display to show the measurement results, providing an accurate and immediate readout. In contrast, analogue hardness testers use a mechanical dial to indicate hardness, requiring manual reading.

The role of hardness testers in machine shops

In machine shops, hardness measurement is essential to ensure that the materials used are suitable for the specific application. For example, a component that must withstand high mechanical stresses must have an adequate hardness to avoid deformation or breakage. Hardness testers make it possible to verify that materials meet the required standards, helping to improve the quality and safety of finished products.

Advantages of digital and analogue hardness testers

Digital hardness testers offer several advantages over analogue models. Their ability to provide accurate and fast readings reduces the margin for human error and increases the efficiency of the measurement process. In addition, many digital hardness testers are equipped with advanced features, such as data storage and the ability to transfer measurements to a computer for further analysis.

On the other hand, analogue hardness testers, although less technologically advanced, are appreciated for their robustness and reliability. They do not require a power supply, which makes them ideal for use in harsh environments or in situations where access to electricity is limited.

How to use hardness testers correctly

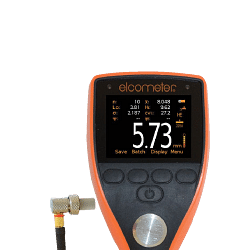

The correct use of hardness testers is crucial for accurate measurements. First of all, it is important to select the right type of hardness tester for the material to be tested. For example, for metallic materials, Rockwell or Brinell durometers are often used, while for softer materials such as rubber, Shore durometers are preferred.

Once the appropriate hardness tester has been selected, it is essential to properly prepare the sample to be tested. The surface of the sample must be clean and free of irregularities to prevent them from affecting the measurement. During the test, the hardness tester must be applied perpendicular to the sample surface, exerting constant pressure.

Practical applications of hardness testers in machine shops

Hardness testers find application in a wide range of areas in machine shops. In the production of automotive components, for example, the hardness of materials is a critical factor affecting the safety and performance of vehicles. Durometers are used to test the hardness of parts such as gears, drive shafts and suspensions.

In the aerospace industry, the hardness of materials is equally important, as components must withstand extreme conditions of temperature and pressure. Hardness testers help ensure that the materials used can withstand these conditions without compromising the safety of the aircraft.

Frequently asked questions about hardness testers

1. What is the difference between a digital and an analogue hardness tester?

The main difference lies in the reading method. Digital hardness testers offer an accurate electronic reading, whereas analogue hardness testers require a manual reading via a mechanical dial.

2. What are the factors to consider when choosing a hardness tester?

It is important to consider the type of material to be tested, the working environment and specific measurement requirements. For example, for difficult environments, an analogue hardness tester might be more suitable.

3. How do you calibrate a hardness tester?

Calibrating a hardness tester is essential to ensure accurate measurements. This process involves the use of standard hardness blocks to check and adjust the accuracy of the instrument.

4. Do hardness testers require maintenance?

Yes, hardness testers require regular maintenance to maintain their accuracy. This includes cleaning the contact surfaces and periodically checking the calibration.

5. Can a hardness tester be used for all types of materials?

No, there are different types of hardness testers designed for specific materials. It is important to select the appropriate durometer according to the material to be tested.

Conclusion: the importance of hardness testers in machine shops

In conclusion, digital and analogue hardness testers are indispensable tools in machine shops to ensure product quality and safety. Their ability to accurately measure the hardness of materials makes it possible to select the most suitable materials for specific applications, thereby improving the performance and durability of components. Whether you choose a digital hardness tester for its accuracy and advanced functionality or an analogue model for its robustness, the important thing is to use the instrument correctly and maintain it properly to obtain reliable results.

Read More Read Less