< Measuring and precision tools Analogue micrometers

Analogue micrometers are an essential tool in machine shops, where precision is essential to ensure the quality and reliability of manufactured components. These measuring instruments, also known as micrometer gauges, are used to measure the dimensions of small and complex objects with extreme accuracy. In this in-depth look, we will explore in detail what analogue micrometers are, how they work, their advantages and practical applications in machine shops.

Understanding analogue micrometers

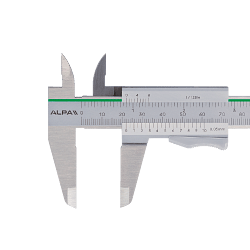

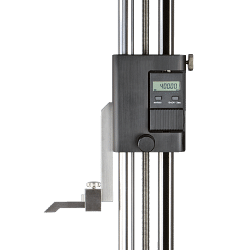

Analogue micrometers are measuring instruments that use a mechanical system to determine the size of an object. They consist of a U-shaped frame, a movable spindle, a graduated drum and a fixed rod. The spindle is brought closer to the object to be measured by means of a micrometer screw, and the measurement is read off on the graduated drum. The accuracy of an analogue micrometer is generally 0.01 millimetres, making it ideal for measurements requiring a high degree of accuracy.

The operation of analogue micrometers

The operating principle of analogue micrometers is based on the micrometer screw, which transforms a small rotary movement into a precise linear movement. When the drum is rotated, the spindle moves linearly towards the object to be measured. The graduated scale on the drum and fixed spindle allows the measurement to be read off accurately. The reading is made by combining the position of the drum with that of the rod, allowing an accurate measurement to be obtained.

Advantages of analogue micrometers

One of the main advantages of analogue micrometers is their reliability. Being mechanical instruments, they do not require a power supply and are less prone to failure than digital devices. In addition, analogue micrometers offer a tactile feel that can be useful for experienced operators, allowing them to perceive any irregularities during measurement. Robustness and durability are further advantages that make these instruments ideal for use in industrial environments.

Practical applications in machine shops

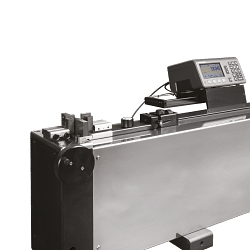

In machine shops, analogue micrometers are used for a wide range of applications. They are essential for quality control, where measurement accuracy is crucial to ensure that components meet design specifications. They are used in the production of mechanical parts, metalworking and the manufacture of precision instruments. In addition, analogue micrometers are used to measure thicknesses, outer and inner diameters, and depths of holes.

Frequently asked questions about analogue micrometers

1. How do I calibrate an analogue micrometer?

Calibrating an analogue micrometer is essential to ensure accurate measurements. It starts by thoroughly cleaning the spindle and fixed rod. Next, a calibration block of known dimensions is used to check the accuracy of the instrument. If necessary, adjustments are made using the calibration screw on the micrometer.

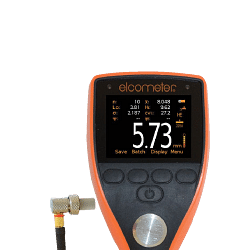

2. What are the differences between analogue and digital micrometers?

Digital micrometers offer direct readings on an electronic display, eliminating the need to interpret graduated scales. However, analogue micrometers are preferred in environments where reliability and robustness are a priority, as they do not require batteries and are less prone to electronic failure.

3. How is an analogue micrometer maintained?

Maintenance of an analogue micrometer includes regular cleaning of the contact surfaces and graduated scales. It is important to avoid exposure to moisture and dust, and to lubricate the micrometer screw periodically to ensure smooth operation.

Conclusions

Analogue micrometers are indispensable tools in machine shops, where precision and reliability are essential. Their ability to provide accurate measurements and their robustness make them ideal for a wide range of industrial applications. Understanding how they work and the benefits they offer is crucial to realising their full potential and ensuring the quality of finished products. With proper calibration and maintenance, analogue micrometers will continue to be reference instruments for precision measurements in machine shops.

Read More Read Less