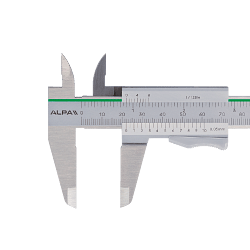

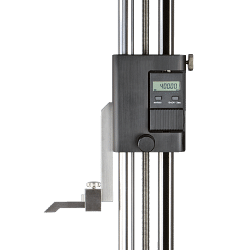

< Measuring and precision tools Analogue calipers

Analogue gauges are an essential tool in the world of machine shops, a sector where precision and accuracy are paramount. These measuring instruments, also known as slide gauges, are used to precisely determine the dimensions of an object, be it a mechanical component or a workpiece. Their importance is such that, despite the advent of digital gauges, analogue gauges continue to be preferred by many professionals for their reliability and ease of use.

The importance of analogue gauges in machine shops

In the context of machine shops, analogue gauges are indispensable tools for ensuring that the components produced meet the required specifications. The ability to accurately measure internal and external diameters, depths and lengths is crucial to ensure that each part fits its purpose perfectly. Analogue gauges offer a direct and immediate readout without the need for batteries or electronics, making them extremely reliable in intensive work environments.

How analogue gauges work

Analogue gauges consist of a main body with a graduated scale and a moving slide running along it. The main scale is usually graduated in millimetres or inches, while the nonius, a secondary scale, allows fractions of units to be read with great accuracy. To use an analogue gauge, the operator must place the part to be measured between the jaws of the gauge and read the measurement on the main scale and the nonius. This method of measurement requires some skill and practice, but offers a level of accuracy that is difficult to match with other instruments.

Advantages of analogue gauges

One of the main advantages of analogue gauges is their robustness. Because they have no electronic components, they are less prone to failure and can be used in harsh environments without the risk of damage from dust, moisture or shock. In addition, analogue gauges do not require batteries, which makes them always ready for use. Their simple construction also makes them easy to calibrate and maintain, ensuring accurate measurements over time.

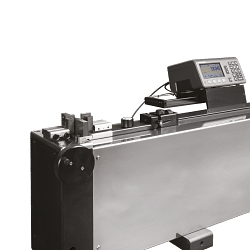

Practical applications of analogue gauges

Analogue gauges find applications in a wide range of industries. In machine shops, they are used to check the dimensions of machined parts, ensuring that they meet the tolerances specified in technical drawings. In the automotive industry, they are used to check the dimensions of critical components such as pistons and cylinders. Even in the aerospace industry, where accuracy is of paramount importance, analogue gauges are reference tools for quality control.

Frequently asked questions about analogue gauges

1. What is the difference between an analogue and a digital gauge?

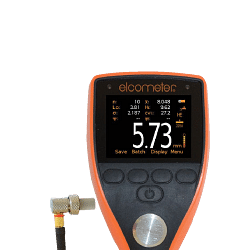

Analogue gauges use a graduated scale and a nonius to provide measurements, whereas digital gauges show the measurement on an electronic display. Analogue gauges are more robust and do not require batteries, whereas digital gauges offer a more immediate reading and are easier for the inexperienced to use.

2. How do I calibrate an analogue gauge?

Calibrating an analogue gauge requires the use of precision calibration blocks. The operator must check that the gauge reading exactly matches the size of the calibration block. If necessary, adjustments can be made to correct any discrepancies.

3. What are typical tolerances for analogue gauges?

Tolerances for analogue gauges depend on the quality of the instrument and its maintenance. In general, high quality gauges can offer an accuracy of up to 0.02 mm.

4. Can analogue gauges be used to measure soft materials?

Yes, analogue gauges can be used to measure soft materials, but it is important to apply minimal pressure to avoid deforming the material and obtaining an inaccurate measurement.

5. What are the best practices for maintaining analogue gauges?

To keep analogue gauges in optimal condition, it is important to clean them regularly to remove dust and debris. In addition, it is advisable to lightly lubricate the sliding surfaces to ensure smooth movement of the caliper. Finally, it is important to store the calipers in a dry and protected place when not in use.

Conclusions

Analogue gauges continue to be an essential tool in machine shops and many other industries. Their accuracy, reliability and ease of use make them a preferred choice for many professionals. Despite the advancement of technology and the introduction of digital instruments, analogue gauges retain an irreplaceable role due to their ability to provide accurate measurements in any working condition. For those working in the mechanical industry, understanding the use and maintenance of analogue gauges is essential to ensure the quality and accuracy of finished products.

Read More Read Less