< Lubricants for machine tools Air coolers

Compressed air coolers are essential components in many industrial applications, especially in machine shops, where efficiency and reliability of operations are paramount. These devices play a crucial role in ensuring that the compressed air used in production processes is free of moisture and contaminants, thereby improving the quality of the end product and extending equipment life.

The role of compressed air coolers in machine shops

In machine shops, compressed air is often used to power a wide range of tools and machinery, from pneumatic drills to presses. However, the compressed air generated by compressors is hot and humid, which can cause significant problems if not properly treated. Moisture in compressed air can lead to corrosion of equipment, contamination of products and operational inefficiencies. Compressed air coolers are designed to reduce the temperature of compressed air, allowing it to condense and remove moisture before the air enters the system.

How compressed air coolers work

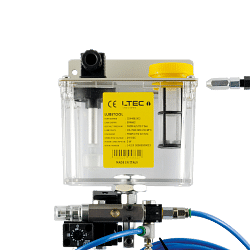

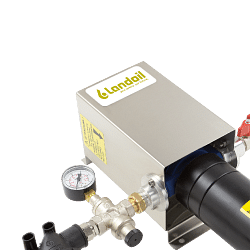

Compressed air coolers operate on a relatively simple principle: warm, moist air is passed through a heat exchanger system, where it is cooled by an external air stream. This cooling process causes the water vapour in the compressed air to condense, which is then collected and removed from the system. There are different types of compressed air coolers, including plate coolers and tube coolers, each with its own specific characteristics and advantages.

Advantages of using compressed air coolers

The implementation of compressed air coolers in machine shops offers numerous advantages. Firstly, they reduce the risk of corrosion and damage to equipment, prolonging its life and reducing maintenance costs. Furthermore, they improve the energy efficiency of the compressed air system, as cooler, drier air is easier to compress than warm, moist air. This results in lower energy consumption and reduced operating costs. Finally, high-quality compressed air improves the precision and reliability of production processes, helping to ensure the quality of the final product.

Considerations when choosing the right compressed air cooler

When choosing a compressed air cooler for a machine shop, it is important to consider several factors. The capacity of the cooler must be adequate for the volume of compressed air used, and the device must be compatible with the existing system. Furthermore, it is essential to assess the energy efficiency of the cooler and its impact on overall operating costs. Finally, ease of maintenance and availability of spare parts are important considerations to ensure continuous and trouble-free operation.

Frequently asked questions about air coolers

1. What is the difference between a compressed air cooler and a dryer?

A compressed air cooler reduces the temperature of the compressed air to remove moisture, whereas a dryer further removes residual moisture to achieve completely dry compressed air.

2. How often does a compressed air cooler need to be serviced?

Maintenance depends on the model and use, but it is generally advisable to carry out regular checks and periodic cleaning to ensure optimum operation.

3. Are compressed air coolers suitable for all industrial applications?

Although they are suitable for many applications, it is important to assess the specific needs of the system to determine whether a compressed air cooler is the best solution.

4. What are the signs of a malfunctioning compressed air cooler?

Common signs include an increase in compressed air temperature, the presence of moisture in the system and a drop in overall performance.

5. Can a compressed air cooler be installed in an existing system?

Yes, many compressed air coolers are designed to be easily integrated into existing systems, but it is important to consult an expert to ensure proper installation.

In conclusion, compressed air coolers are indispensable tools for machine shops wishing to optimise the efficiency of their production processes and ensure the quality of the end product. With a thorough understanding of how they work and the benefits they offer, companies can make informed choices to improve their operations and reduce operating costs.

Read More Read Less