< Hand tools Tubular wrenches

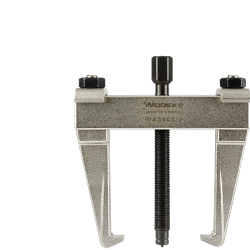

Tubular spanners are an essential tool in machine shops and manufacturing industries. These tools, known for their versatility and precision, are designed to facilitate the tightening and loosening of nuts and bolts in tight spaces where other tools might be ineffective. Their tubular design allows them to reach depths and angles that would otherwise be inaccessible, making them indispensable for professionals.

The importance of tubular spanners in machine shops

Tubular spanners are particularly appreciated in machine shops for their ability to adapt to different sizes of nuts and bolts. This makes them a versatile tool that can reduce the number of tools needed in a workshop. Their robust construction and ergonomic design ensure a secure grip and prolonged use without fatiguing the operator. In addition, the possibility of using extensions and additional accessories further extends their applications, allowing complex mechanical components to be worked on more efficiently.

How to use spanners correctly

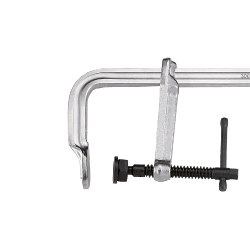

The correct use of tubular spanners is crucial to ensure the safety and effectiveness of the work performed. Before starting, it is important to select the appropriate size spanner for the nut or bolt you intend to work on. A spanner that is too large or too small could damage the component or compromise the safety of the operator. Once the right spanner has been selected, it is essential to apply an even and controlled force to avoid damaging the thread of the bolt or nut. In case of excessive resistance, it is advisable to use specific lubricants to facilitate the operation.

Advantages of using tubular spanners

The adoption of tubular spanners in mechanical operations offers several advantages. First of all, their ability to reach deep and narrow spaces allows working on components that would otherwise require the disassembly of adjacent parts, saving time and reducing labour costs. In addition, their robust and wear-resistant design ensures a long service life, reducing the need for frequent replacement. Tubular spanners are also compatible with a wide range of accessories, such as extensions and adapters, which further expand their possibilities of use.

Frequently asked questions on the use of tubular spanners

One of the most common questions concerns the difference between socket spanners and tubular spanners. Although both are used for tightening and loosening nuts and bolts, socket spanners are generally longer and designed to reach deeper spaces. Another frequently asked question concerns the maintenance of tubular spanners. It is important to clean the tools regularly to remove oil residues and dirt, and to store them in a dry environment to prevent rust. Finally, many people wonder whether tubular spanners are suitable for use on vehicles. The answer is yes, as their versatility makes them ideal for maintenance and repair operations on cars and motorbikes.

Conclusions

Tubular spanners are an essential item for those working in the mechanical and industrial sectors. Their ability to adapt to different operating situations, combined with their robustness and ease of use, makes them an indispensable tool for ensuring efficiency and precision in maintenance and repair work. Investing in high-quality tubular spanners means equipping yourself with a reliable and long-lasting ally, capable of successfully tackling the daily challenges of mechanical workshops.

Read More Read Less