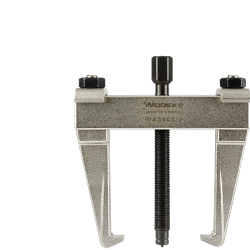

< Hand tools T-wrenches

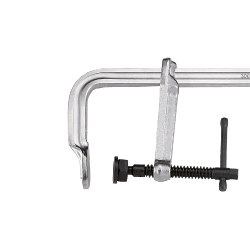

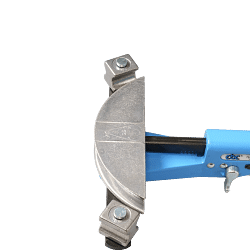

T-handle spanners are an essential tool in the mechanical workshop landscape, an item that cannot be missing from a professional mechanic's toolkit. These tools, known for their distinctive 'T' shape, are designed to offer optimal leverage and precise control when applying torque to bolts and nuts. Their versatility and reliability make them indispensable for a wide range of industrial and mechanical applications.

The importance of T-keys in mechanical workshops

T-keys are particularly appreciated for their ability to reach tight spaces that are difficult to manoeuvre with other types of spanners. Their design allows a uniform force to be applied, reducing the risk of damaging the components being worked on. This is especially important in machine shops, where precision and reliability are crucial to guarantee the quality of the work performed.

Technical characteristics of T-keys

T-keys are available in different sizes and materials, each designed for specific applications. The most common are made of chrome-vanadium steel, a material known for its strength and durability. Some variants may include ergonomic handles to improve comfort during prolonged use. In addition, T-keys can be equipped with interchangeable tips, making them even more versatile and adaptable to different needs.

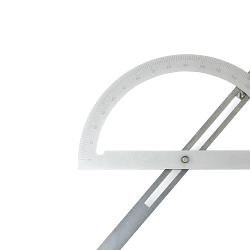

Using T-keys: practical tips

The correct use of T-keys is crucial for best results. It is important to select the appropriate size for the nut or bolt you are working on, to avoid damaging both the tool and the component. In addition, it is advisable to apply constant and controlled pressure, using the leverage offered by the T-shape to facilitate the operation. In the case of particularly stubborn bolts, the use of lubricants can help reduce friction and facilitate removal.

Advantages of T-keys compared to other tools

Compared to other spanner types, T-keys offer several advantages. Their shape allows for greater leverage, reducing the effort required to tighten or loosen bolts. In addition, the ability to reach into tight spaces makes them particularly useful in applications where space is limited. Their robust construction ensures a long service life, even under intensive use.

Frequently asked questions about T-handle spanners

1. What is the difference between a T-handle spanner and a ratchet spanner?

T-keys offer greater leverage and are ideal for applications requiring constant force. Ratchet spanners, on the other hand, are better suited for operations that require speed and ease of movement, due to the ratchet mechanism that allows you to work without having to remove the spanner from the bolt.

2. How do I choose the right size of T-handle spanner?

Choosing the right size depends on the diameter of the bolt or nut you intend to work on. It is important to use the correct size spanner to avoid damaging both the tool and the component.

3. Can T-keys be used on different materials?

Yes, T-keys can be used on a variety of materials, as long as the appropriate size and type of bit is chosen for the specific material.

Conclusion: the indispensability of T-keys

In conclusion, T-keys are indispensable tools in machine shops due to their versatility, robustness and ability to offer optimal leverage. Their importance cannot be underestimated, as they contribute significantly to the efficiency and precision of mechanical work. Choosing the right T-keys and using them correctly can make the difference between a job well done and one that requires further work. For mechanics, investing in high-quality T-keys is a decision that pays off over time, guaranteeing excellent results and increased customer satisfaction.

Read More Read Less