Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Register and use the discount code NEWWELCOME to get 10% off on your first purchase. GET DISCOUNT.

Free shipping in 24h from 200€

Catalogues

Customer service

How can we help you?

- Faq

- Customer service

02.927371

- Supporting big orders

02.38298620

-

info@linkindustrialtools.it

- Request assistance with form

Or contact us with the chat in the lower right corner

- All products

Integral cutting tools

Integral cutting tools Turning tools

Turning tools Thread tools

Thread tools Thread tools

Thread tools- All products

- Thread inserts

Milling cutters

Milling cutters Drilling tools

Drilling tools Drilling tools

Drilling tools- All products

- Indexable drill bits

- Indexable drill heads

Clamping systems

Clamping systems Measuring and precision tools

Measuring and precision tools Measuring and precision tools

Measuring and precision tools- All products

- Digital calipers with readings to 0.01

- Analogue calipers

- Digital micrometers

- Analogue micrometers

- Bore gauges

- Snap gauges

- Digital gauges

- Analogue gauges

- Touch probes

- Zero setters and edge finders

- Inspection plates

- Altimeters

- Height gauges

- Squares and levels

- Threaded rings

- Gauge blocks

- Calibrated tapes and thickness gauges

- Digital and analogue hardness testers

- Roughness testers

- Microscopes, lenses and visors

- Digital thermo-hygrometer to measure moisture

- Reset benches

- Optical profile projector

- Professional, digital dynamometers

- Laboratory scales

- Digital amperometric pliers

- Thickness and adhesion gauges

Hand tools

Hand tools Hand tools

Hand tools- All products

- Combination wrenches

- Spanners

- Hook wrenches

- Tubular wrenches

- Hexagon keys

- Torx wrench

- Socket wrenches

- Screwdrivers

- Torque wrenches

- Torque screwdriver

- Inserts and bits for screw drivers

- Tool trolleys

- Workshop pliers

- Wire strippers

- Cable strippers

- Cutting nippers

- Professional scissors

- Nippers

- Professional shears

- American or Swedish pipe wrench

- Adjustable wrench

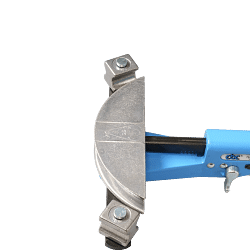

- Pipe tools

- Pipe cutter for plumber

- Cutter

- Hacksaws

- Deburring tools

- Chisels

- Hammers and mallets

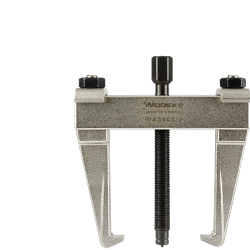

- Mechanical and conical pullers

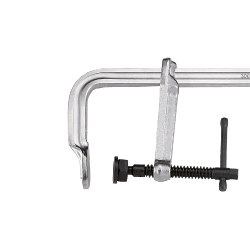

- Clamps

- Tap wrenches and die stocks

- Riveters

- Flexometers

- Tape measures

- Markers

- Flat squares and rulers

- Professional dividers

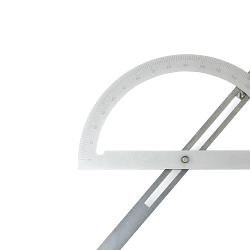

- Professional protractors

- Brushes

- Lubricators and spray nozzles

- T-wrenches

- Reversible ratchets

Abrasives

Abrasives Abrasives

Abrasives- All products

- Cutting discs

- Deburring grinding wheel

- Flap discs

- Fabric discs for surface treatment

- Abrasive fibre discs with Velcro

- Abrasive cloth in rolls, sheets and bands

- Flap wheels with pin and abrasive wheel with hole

- Abrasive wheels for buffing machines

- Abrasive spiral bands

- Abrasive brushes

- Flexible sanders

- Mounted grinding discs

- Polishing felt

- Solid carbide rotary cutters

- HSS rotary cutters

- Abrasive wheels for sharpening and grinding

- Diamond grinding wheels

- Grinding stone

- Diamond paste

- Abrasive stones

- Files and rasps

- Diamond files

- Grinders and polishing equipment

Lubricants for machine tools

Lubricants for machine tools Lubricants for machine tools

Lubricants for machine tools- All products

- Water-miscible coolants

- Neat cutting oil

- Minimal lubrication systems

- Oil for guides and slides

- Drums of hydraulic oil fluid

- Anti-freeze for machine tools

- Air coolers

- Oil separator

- Powders and absorbents for oil

- Aspirators for oil mist

- Accessories for cooling lubricants

- Metal and mould protectors

- Grease and paste

Chemical, adhesives and sealants

Chemical, adhesives and sealants Chemical, adhesives and sealants

Chemical, adhesives and sealants- All products

- Acrylic, cyanoacrylate and epoxy adhesives

- Guns and silicon sealant

- Threadlocker

- Sealants and retainers

- Release agents, lubricants and anti-seize

- Zinc spray and polishes

- Lubrication accessories

- Protections for maintenance

- Industrial Cleansing

- Handwash

- Industrial cloths and rags

- Welding machines

- Electrodes

- Clamps, shields and welding masks

- Antispatter

Safety equipment

Safety equipment Pneumatics

Pneumatics Lifting systems

Lifting systems Workshop equipment

Workshop equipment Workshop equipment

Workshop equipment- All products

- Column and bench drills

- Accessories for lathes

- Band saws

- Cut-off machines

- Bench grinders

- Power tools

- Spare parts and accessories for Power Tools

- Saws and hole cutters: wood, metal and plasterboard

- Tapered cutters for sheet metal

- Industrial aspirators

- Fume aspirators

- Bench vices

- Technical lamps

- LED torches

- Industrial cable winders

- Trolley wheels

- Quick clamps

- Threaded inserts

- Control knobs

- Packaging accessories and material

- Belt sanders

- Electric tapping machines

Furnishings and storage

Furnishings and storage Furnishings and storage

Furnishings and storage- All products

- Work benches

- Swivel chairs for office use

- Drawer units for workshops

- Industrial cabinets for warehouses and workshops

- Tool cabinets

- Security cabinets

- Changing room cabinets

- Containers for small metal parts

- Scrap holders

- Workshop trolleys

- Spill pallets for drum storage

- Shelves for warehouses and offices

- Cantilever shelving

- Aluminium ladders

- Modular plinths

- Units and cabinets for waste recycling

Brand

BrandPromotions

Bestseller

Bestseller- Catalogues

-

Catalogues

Customer service

How can we help you?

- Faq

- Customer service

02.927371

- Supporting big orders

02.38298620

-

info@linkindustrialtools.it

- Request assistance with form

Or contact us with the chat in the lower right corner

< Hand tools

- Home

- Hand tools

- Markers

Markers

In the context of machine shops, markers are essential tools for ensuring precision and traceability in production processes. These devices, often underestimated, play a crucial role in improving operational efficiency and the quality of the end product. In this in-depth look, we will explore in detail what markers are, what they are used for, how they are used and what benefits they offer to machine shops.

Introduction to markers in the machine industry

Markers are tools used to imprint information on surfaces of various materials, such as metal, plastic and wood. This information can include serial numbers, barcodes, company logos and other identification required for traceability and quality management. In the mechanical engineering industry, the use of markers is essential to ensure that each component can be identified and traced throughout the production chain.

Types of markers and their applications

There are different types of markers, each with specific applications and advantages. Among the most common are laser markers, ink-jet markers and micro-percussion markers.

- Laser markers: They use a laser beam to permanently engrave information on the surface of the material. They are ideal for applications requiring high precision and durability, such as marking metal components in harsh industrial environments.

- Ink jet markers: They spray ink onto the surface of the material to create temporary or permanent markings. They are often used for marking plastic products or for applications requiring high production speed.

- Micro-percussion markers: They use a needle that strikes the surface of the material to create a permanent mark. They are particularly suitable for hard materials and for applications requiring deep and durable marking.

Advantages of using markers in machine shops

The adoption of markers in machine shops offers numerous advantages, including:

- Improved traceability: The ability to mark each component with a unique identifier allows the product to be traced throughout the production chain, facilitating quality management and troubleshooting.

- Operational efficiency: Automating the marking process reduces the time needed to identify and manage components, improving the overall efficiency of operations.

- Error reduction: Automated marking reduces the risk of human error, ensuring that information is always correct and legible.

- Regulatory compliance: Many industries require marking of components to comply with safety and quality regulations. The use of markers ensures that machine shops can meet these requirements.

How to choose the right marker for your workshop

Choosing the right marker depends on several factors, including the type of material to be marked, the required production speed and the available budget. It is important to carefully evaluate the specific needs of your workshop and compare the characteristics of different types of markers to determine which is the most suitable.

Frequently asked questions about markers

1. What is the difference between laser and inkjet marking?

Laser marking is permanent and suitable for hard materials, whereas inkjet marking can be temporary and more suitable for soft materials or high-speed applications.

2. Can laser markers damage the material?

When used correctly, laser markers do not damage the material. It is important to adjust the laser power according to the type of material to avoid damage.

3. What are the costs associated with the implementation of markers?

Costs vary depending on the type of marker and its characteristics. It is important to consider not only the initial cost, but also operational and maintenance costs.

4. Is it possible to mark uneven surfaces?

Yes, many markers are designed to adapt to uneven surfaces, ensuring clear and legible marking.

5. How is a marker maintained in good condition?

Regular maintenance, including cleaning the marking heads and checking settings, is essential to ensure optimal performance and long life of the marker.

Conclusion

Markers are indispensable tools for machine shops wishing to improve the traceability, efficiency and quality of their production processes. With a wide range of options available, you can find the perfect marker to meet the specific needs of your workshop. Investing in the right markers not only improves day-to-day operations, but also ensures that your workshop remains competitive in an ever-changing market.

Read More Read LessIntroduction to markers in the machine industry

Markers are tools used to imprint information on surfaces of various materials, such as metal, plastic and wood. This information can include serial numbers, barcodes, company logos and other identification required for traceability and quality management. In the mechanical engineering industry, the use of markers is essential to ensure that each component can be identified and traced throughout the production chain.

Types of markers and their applications

There are different types of markers, each with specific applications and advantages. Among the most common are laser markers, ink-jet markers and micro-percussion markers.

- Laser markers: They use a laser beam to permanently engrave information on the surface of the material. They are ideal for applications requiring high precision and durability, such as marking metal components in harsh industrial environments.

- Ink jet markers: They spray ink onto the surface of the material to create temporary or permanent markings. They are often used for marking plastic products or for applications requiring high production speed.

- Micro-percussion markers: They use a needle that strikes the surface of the material to create a permanent mark. They are particularly suitable for hard materials and for applications requiring deep and durable marking.

Advantages of using markers in machine shops

The adoption of markers in machine shops offers numerous advantages, including:

- Improved traceability: The ability to mark each component with a unique identifier allows the product to be traced throughout the production chain, facilitating quality management and troubleshooting.

- Operational efficiency: Automating the marking process reduces the time needed to identify and manage components, improving the overall efficiency of operations.

- Error reduction: Automated marking reduces the risk of human error, ensuring that information is always correct and legible.

- Regulatory compliance: Many industries require marking of components to comply with safety and quality regulations. The use of markers ensures that machine shops can meet these requirements.

How to choose the right marker for your workshop

Choosing the right marker depends on several factors, including the type of material to be marked, the required production speed and the available budget. It is important to carefully evaluate the specific needs of your workshop and compare the characteristics of different types of markers to determine which is the most suitable.

Frequently asked questions about markers

1. What is the difference between laser and inkjet marking?

Laser marking is permanent and suitable for hard materials, whereas inkjet marking can be temporary and more suitable for soft materials or high-speed applications.

2. Can laser markers damage the material?

When used correctly, laser markers do not damage the material. It is important to adjust the laser power according to the type of material to avoid damage.

3. What are the costs associated with the implementation of markers?

Costs vary depending on the type of marker and its characteristics. It is important to consider not only the initial cost, but also operational and maintenance costs.

4. Is it possible to mark uneven surfaces?

Yes, many markers are designed to adapt to uneven surfaces, ensuring clear and legible marking.

5. How is a marker maintained in good condition?

Regular maintenance, including cleaning the marking heads and checking settings, is essential to ensure optimal performance and long life of the marker.

Conclusion

Markers are indispensable tools for machine shops wishing to improve the traceability, efficiency and quality of their production processes. With a wide range of options available, you can find the perfect marker to meet the specific needs of your workshop. Investing in the right markers not only improves day-to-day operations, but also ensures that your workshop remains competitive in an ever-changing market.