Hammers and mallets

In the context of machine shops, the use of hammers and mallets is essential to ensure precision, efficiency and safety in daily operations. These tools, available in various types and sizes, are designed to meet the specific needs of different industrial and craft applications.

Hammers are essential tools for a wide range of mechanical operations. The main variants include:

- Carpenters' hammers: Used mainly for carpentry work, these hammers are equipped with a forked head for extracting nails.

- Blacksmith's hammers: Featuring a heavy, flat head, ideal for shaping hot metal.

- Mechanic's hammers: With a hardened steel head, they are used for precision work on mechanical components.

- Rubber hammers: Perfect for not damaging delicate surfaces, such as when working on glass or sheet metal.

Hammers are similar tools to hammers, but are distinguished by their larger and heavier head, often made of different materials such as wood, rubber or metal. The main variants include:

- Wooden mallets: Used for carpentry work and for striking delicate tools without damaging them.

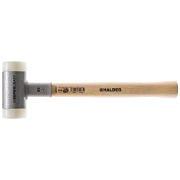

- Rubber mallets: Ideal for assemblies requiring force without leaving marks or dents.

- Metal mallets: Used in industrial environments for work requiring greater force and precision.

The use of hammers and mallets in machine shops offers numerous advantages:

- Precision: Tools designed for specific jobs guarantee high precision in operations.

- Durability: Made of high-quality materials, these tools are resistant to wear and impact.

- Versatility: The variety of shapes and sizes make them suitable for different applications, from assembly to maintenance.

- Safety: The ergonomic, non-slip handle reduces the risk of injury during use.

In machine shops, hammers and mallets are used in numerous processes, including:

- Assembly and disassembly: Essential for assembling and disassembling mechanical components.

- Metalworking: Used to shape, finish and fit metal parts.

- Maintenance: Essential tools for routine and extraordinary maintenance of machinery.

Choosing the right hammers and mallets is crucial to improving the efficiency and quality of work in machine shops. Investing in quality tools means guaranteeing longevity and precision, which are essential for maintaining high standards of production and safety.