< Hand tools Flat squares and rulers

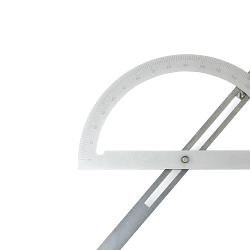

In the world of machine shops, accuracy and precision are key elements in guaranteeing the quality of the work performed. Among the essential tools for carpenters, scales and squares play a major role. These tools, although they may seem simple, are at the heart of many measuring and marking operations, and their correct application can make the difference between a job well done and one that needs correction.

The importance of carpenters' scales and squares

Scales and squares are measuring tools used to draw straight lines and precise angles on various materials. Their importance lies in their ability to ensure that each machined part conforms to the required specifications, minimising errors and optimising the production process. In an industrial context, where precision is synonymous with efficiency and quality, the use of scales and squares is indispensable.

Technical characteristics of scales and squares

Carpenters' scales are generally made of stainless steel or aluminium, materials that offer strength and durability. The surfaces of these scales are often engraved with metric or imperial scales, allowing for precise measurements. The squares, on the other hand, are designed to ensure the formation of perfect angles, usually 90 degrees, but may also include other angles depending on the specific needs of the job.

Practical use of rulers and squares

The use of scales and squares in a machine shop is varied and depends on the type of work to be performed. For example, during the scribing phase, a ruler can be used to mark cutting lines on a piece of metal, while a square can be used to check the perpendicularity of a corner. These tools are also essential in the assembly phase, where the accuracy of angles and guide lines is crucial for the correct assembly of components.

Advantages of using scales and squares

There are several advantages to using high-quality scales and squares. First of all, they guarantee greater accuracy in measurements, reducing the margin of error and improving the quality of the final product. Furthermore, the use of reliable tools speeds up the machining process, as it reduces the need for trimming and corrections. Finally, the investment in quality tools results in greater durability, reducing replacement and maintenance costs.

Frequently asked questions on the use of scales and squares

One of the most common questions concerns the maintenance of these tools. It is essential to keep scales and squares clean and free of debris to ensure accurate measurements. It is also advisable to periodically check the accuracy of the engraved scales and angles, especially if the instruments have been subjected to heavy wear and tear.

Another frequently asked question concerns the choice of material. Although stainless steel is often preferred for its resistance to corrosion, aluminium may be a good choice for those seeking lightness and ease of handling, especially in applications that do not require extreme strength.

Conclusion: the essence of precision in machine shops

In summary, carpenters' scales and squares are indispensable tools in machine shops. Their ability to guarantee precision and accuracy in measuring and marking is crucial to the success of any project. Investing in quality tools and understanding their correct use not only improves operational efficiency, but also helps to raise the quality standards of the end product. In an industry where precision is everything, scales and squares are an irreplaceable ally for every carpenter.

Read More Read Less