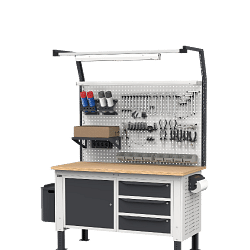

< Furnishings and storage Work benches

Workbenches are essential tools in any machine shop, representing the beating heart of many daily operations. These robust workbenches not only provide a stable and durable surface to perform a wide range of tasks, but are also designed to improve the efficiency and safety of operators. In this in-depth look, we will explore in detail what workbenches are, what they are used for, how they are used, the benefits of using them, and answer some frequently asked questions.

What are workbenches?

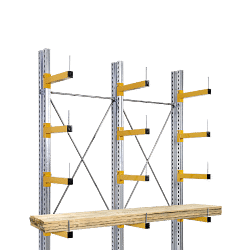

Workbenches are structures designed to provide a stable and durable work surface suitable for a variety of industrial and craft activities. Usually made of sturdy materials such as steel, solid wood or a combination of both, workbenches are designed to withstand heavy loads and daily wear and tear. Their solid construction makes them ideal for use in industrial environments where durability is paramount.

What are workbenches used for?

Workbenches serve multiple purposes in machine shops. They are used to assemble components, perform repairs, take precise measurements and even for simple storage of tools and materials. Their versatility makes them indispensable for any operation requiring a reliable work surface. In addition, many workbenches are equipped with integrated drawers and shelves, which provide additional space for organising tools, further improving operational efficiency.

How are workbenches used?

The use of workbenches varies depending on the specific needs of the workshop. However, there are some common practices that can optimise the use of these tools. First of all, it is important to place the workbench in a well-lit and easily accessible area to ensure that operators can work in optimal conditions. Furthermore, keeping the workbench tidy and organised is essential to improve productivity and reduce the risk of accidents. Tools and materials should be stored logically, with the most frequently used items within easy reach.

Benefits of using workbenches

The use of workbenches offers numerous benefits, which go beyond simply providing a work surface. One of the main benefits is the increase in operational efficiency. With a well-organised workbench, operators can quickly access the tools and materials they need, reducing downtime and improving overall productivity. In addition, workbenches help to improve workplace safety. A stable work surface reduces the risk of accidents, while the organisation of tools minimises the risk of injury caused by misplaced objects.

Answers to frequently asked questions

1. What is the difference between a workbench and a normal table?

The main difference lies in construction and functionality. Workbenches are designed to withstand heavy loads and wear, whereas normal tables may not offer the same durability and stability.

2. How do I choose the right workbench for my workshop?

Choosing the right workbench depends on the specific needs of your workshop. Consider the size of the space available, the type of work that will be done and the maximum load the bench will have to support.

3. Is it possible to customise a workbench?

Yes, many manufacturers offer customisation options to adapt workbenches to your specific needs, such as adding drawers, shelves or electrical outlets.

4. What materials are best for a workbench?

The most common materials are steel and solid wood. Steel offers greater strength and durability, while solid wood may be preferred for work requiring a softer surface.

5. How can I keep my workbench in good condition?

Regular maintenance is essential to prolong the life of your workbench. Cleaning the surface after each use, periodically checking the stability of the legs and lubricating moving parts are recommended practices.

In conclusion, workbenches are indispensable tools in machine shops, offering a combination of durability, functionality and safety. Their ability to improve operational efficiency and safety makes them a valuable investment for any industrial environment. Choosing the right workbench and keeping it in good condition can make a significant difference in productivity and the quality of work performed.

Read More Read Less