< Clamping systems Vises

Vises are essential tools in machine shops, used to securely clamp parts during machining operations. These devices, although they may seem simple, are essential to ensure precision and safety in a wide range of mechanical operations. In this in-depth look, we will explore in detail what vices are, how they are used, the advantages they offer and answer some of the most frequently asked questions about these indispensable tools.

Introduction to vices: a pillar of the machine shop

Vices are clamping devices designed to hold an object in a fixed position while it is being machined. They mainly consist of two jaws, one fixed and one movable, which move closer together or further apart via a screw mechanism. This simple but effective system allows a considerable force to be applied to clamp the workpiece, ensuring stability and precision.

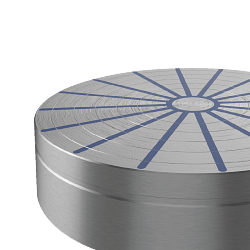

Types of vices and their applications

There are different types of vices, each designed for specific applications. Bench vices are the most common and are used for a wide range of operations, from cutting to drilling. Drill vices, on the other hand, are designed to be mounted on drill presses, allowing workpieces to be clamped during drilling operations. Angle vices allow workpieces to be clamped at different angles, facilitating complex machining operations. Finally, welding vices are made of heat-resistant materials, ideal for holding workpieces in place during welding operations.

Vices materials and construction

Vices are generally made of cast iron or steel, materials that offer excellent strength and durability. The choice of material depends on the specific application and the needs of the workshop. Cast-iron vices are appreciated for their ability to absorb vibrations, while steel vices offer greater resistance to deformation under load.

Advantages of using vices in machining operations

The use of vices offers numerous advantages in machining. First of all, they guarantee a firm and secure grip on the workpiece, reducing the risk of unwanted movements that could compromise the precision of the work. They also improve operator safety, as the workpiece is firmly clamped and does not need to be held manually. Vices also allow working with both hands free, increasing efficiency and productivity.

How to choose the right vice for your workshop

Choosing the right vice depends on several factors, including the type of machining, the size of the parts to be machined and the available budget. It is important to consider the jaw opening capacity, clamping force and material quality. In addition, it is advisable to opt for vices with interchangeable jaws, which can be replaced when worn, thus extending the life of the tool.

Maintenance and care of vices

To ensure a long service life and optimal operation, regular maintenance of the vices is essential. This includes cleaning the jaws and screw mechanism, lubricating moving parts and periodically inspecting them for signs of wear or damage. Proper maintenance not only prolongs the life of the vise, but also ensures that it continues to provide reliable performance.

Frequently asked questions about vices

1. What is the difference between a bench vise and a drill vise?

The main difference lies in the application. Bench vises are used for a variety of manual operations, whereas drill vises are designed to be mounted on drill presses, facilitating drilling operations.

2. How can I increase the lifetime of my vise?

Regular maintenance is essential. Cleaning the jaws, lubricating moving parts and replacing worn jaws are practices that help keep the vice in good condition.

3. Can vices damage workpieces?

If used correctly, vices should not damage workpieces. However, it is important to adjust the clamping force according to the workpiece material and use protective jaws if necessary.

4. What are the best vices for precision machining?

For precision machining, it is advisable to use vices with high-quality jaws and a screw mechanism that allows precise and controlled clamping.

5. Can a welding vise be used for other applications?

Yes, welding vises can be used for other applications, but it is important to consider that they are designed to withstand heat and may not offer the same precision as other types of vises.

Conclusion: the importance of vices in machine shops

Vices are indispensable tools in machine shops, offering stability, precision and safety in machining. Their versatility and robustness make them suitable for a wide range of applications, from the simple clamping of parts during manual machining to the complex fixing of components for precision operations. Choosing the right vice and keeping it in good condition is essential to ensure optimal results and prolong tool life. With a thorough understanding of their features and applications, vices can become an irreplaceable ally for any mechanical professional.

Read More Read Less