< Clamping systems Spindles SK DIN 69871

SK DIN 69871 chucks are an essential component in modern machine shops. These tools, known for their precision and reliability, are essential to guarantee the efficiency and quality of machining operations. In this in-depth look, we will explore in detail what SK DIN 69871 spindles are, how they are used, the advantages they offer and answer some of the most frequently asked questions on this topic.

Introduction to SK DIN 69871 spindles

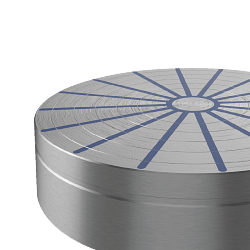

SK DIN 69871 chucks are clamping devices mainly used in machine tools to clamp cutting tools. DIN 69871 defines the technical and dimensional specifications of these chucks, ensuring universal interchangeability and compatibility with machines that support this standard. Their design is geared towards providing high precision and stability during machining operations, making them ideal for applications requiring tight tolerances and high quality surface finishes.

Operation and use of SK DIN 69871 spindles

The operation of SK DIN 69871 spindles is based on a conical clamping system that ensures a rigid and stable coupling between the tool and the machine tool. This system is designed to minimise vibration and ensure high precision during cutting operations. SK DIN 69871 spindles are commonly used in milling machines, lathes and CNC machining centres, where precision and stability are of paramount importance.

Installing an SK DIN 69871 spindle is relatively simple, but requires attention to detail to ensure correct alignment and clamping. It is essential to follow the manufacturer's specifications and use the appropriate tools to avoid damage to the spindle or tool.

Advantages of SK DIN 69871 spindles

Using SK DIN 69871 spindles offers numerous advantages that make them a preferred choice in machine shops. Among the main benefits are:

1. Precision and stability: Thanks to their conical design, SK DIN 69871 spindles offer high precision and stability, minimising vibration and improving machining quality.

2. Interchangeability: compliance with DIN 69871 ensures that the spindles are compatible with a wide range of machine tools, facilitating tool replacement and upgrading.

3. Durability and reliability: made of high-quality materials, SK DIN 69871 spindles are designed to withstand demanding working conditions, offering long life and constant reliability.

4. Versatility: these spindles are suitable for a wide range of applications, from light to heavy machining, making them a versatile solution for different production needs.

5. Ease of maintenance: maintenance of SK DIN 69871 spindles is relatively simple, requiring only regular cleaning and inspection to ensure optimum performance.

Frequently asked questions about SK DIN 69871 spindles

What are the differences between SK DIN 69871 spindles and other spindle types?

SK DIN 69871 spindles are characterised by their conical design and compliance with a specific standard, which guarantees high precision and interchangeability. Other spindle types, such as BT or HSK spindles, may have different characteristics in terms of design and specific applications.

How do I choose the right SK DIN 69871 spindle for my application?

Choosing the right SK DIN 69871 chuck depends on several factors, including the type of machine tool, the material to be machined and the specifications of the cutting tool. It is important to consider the spindle size, clamping capacity and accuracy characteristics required for the specific application.

What are the best maintenance practices for SK DIN 69871 spindles?

To ensure optimum performance and long life, it is essential to follow certain best practices for the maintenance of SK DIN 69871 spindles. These include regular cleaning of the spindle and tool, periodic inspection for signs of wear or damage, and the use of appropriate lubricants to reduce friction and prevent corrosion.

Conclusions

SK DIN 69871 spindles are a crucial component in machining operations, offering precision, stability and reliability. Their compliance with an internationally recognised standard ensures interchangeability and compatibility that simplify integration in machine shops. Choosing the right spindle and maintaining it correctly can make all the difference in terms of machining quality and production efficiency. With a thorough understanding of their characteristics and advantages, workshops can optimise their operations and achieve excellent results.

Read More Read Less