< Clamping systems Chucks MAS 403 BT

MAS 403 BT chucks are an essential component in modern machine shops. These tools, known for their precision and reliability, are essential to guarantee the efficiency and quality of machining operations. In this in-depth look, we will explore in detail what MAS 403 BT spindles are, how they are used, the advantages they offer, and answer the most frequently asked questions in the industry.

Understanding MAS 403 BT spindles

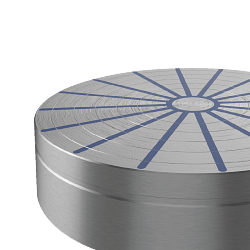

MAS 403 BT chucks are clamping devices mainly used in machine tools to clamp cutting tools. The acronym 'MAS 403 BT' refers to a Japanese standard that defines the technical specifications of these chucks, ensuring compatibility and optimum performance. They are designed to offer high rigidity and precision, which are essential features for machining operations requiring tight tolerances.

The importance of spindles in machining operations

In the context of machine shops, spindles play a crucial role. They ensure that the cutting tool is securely fixed, minimising vibration and improving the quality of the surface finish of the machined part. In addition, a quality spindle like the MAS 403 BT helps extend tool life, reducing overall operating costs.

Advantages of MAS 403 BT spindles

One of the main advantages of MAS 403 BT spindles is their ability to maintain high accuracy even under extreme working conditions. Thanks to their robust construction, these spindles can withstand high loads and high rotation speeds without compromising tool stability. Furthermore, their compatibility with a wide range of machine tools makes them a versatile choice for many industrial applications.

Using MAS 403 BT spindles in workshops

Installing and using MAS 403 BT spindles requires some technical expertise. It is essential to ensure that the spindle is correctly aligned and tightened to avoid problems during machining. In addition, regular maintenance is essential to ensure that the spindle maintains its optimum performance over time. This includes periodic cleaning and checking components for wear.

Frequently asked questions about MAS 403 BT spindles

1. What are the differences between MAS 403 BT spindles and other types of spindles?

MAS 403 BT spindles are distinguished by their compliance with a specific standard, which guarantees greater precision and compatibility. Compared to other spindles, they offer better stability and are designed for high-speed applications.

2. How do I choose the right MAS 403 BT spindle for my application?

The choice of spindle depends on various factors, including the type of machining operation, the tool material and the machine tool specifications. It is advisable to consult an expert to determine the most suitable spindle for your needs.

3. What are the best maintenance practices for MAS 403 BT spindles?

Regular maintenance is crucial to maintain spindle performance. This includes cleaning the contact surfaces, lubricating the moving parts and regularly checking for wear.

Conclusion

MAS 403 BT spindles are an essential element for machine shops striving for machining excellence. Their precision, reliability and versatility make them an ideal choice for a wide range of industrial applications. Investing in quality spindles and ensuring proper maintenance can lead to significant improvements in operational efficiency and end-product quality.

Read More Read Less