< Clamping systems Chucks HSK-A DIN 69893A

HSK-A DIN 69893A chucks are a crucial element in modern machine shops, where precision and efficiency are crucial to success. These tools, known for their ability to guarantee high stability and precision, are essential for anyone working in the metalworking and machine tool sector. In this in-depth look, we will explore in detail what HSK-A DIN 69893A spindles are, what they are used for, how they are used, the advantages they offer and answer some of the most frequently asked questions on this topic.

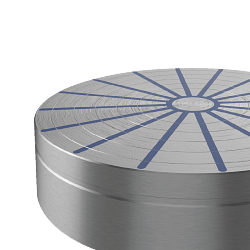

Understanding HSK-A DIN 69893A spindles

HSK-A DIN 69893A spindles are mechanical components used to clamp cutting tools on machine tools. The abbreviation HSK stands for 'Hohlschaftkegel', which means 'hollow-shank cone' in German. This type of chuck is designed to improve accuracy and machining speed compared to conventional Morse or ISO taper chucks. DIN 69893A specifies dimensions and tolerances to ensure interchangeability and compatibility between different manufacturers.

Functionality and applications of HSK-A spindles

HSK-A spindles are designed for high-speed, high-precision applications. Their hollow-shank design allows a more rigid and stable connection between the spindle and the tool, reducing vibration and improving machining quality. This makes them ideal for milling, drilling and turning operations where precision is paramount. Furthermore, their ability to maintain high concentricity even at high rotational speeds makes them particularly suitable for use in advanced CNC machines.

Advantages of HSK-A DIN 69893A spindles

One of the main advantages of HSK-A spindles is their ability to guarantee greater precision than conventional spindles. The hollow shank connection allows uniform force distribution, reducing the risk of misalignment and improving workpiece quality. In addition, HSK-A spindles offer greater rigidity, which translates into reduced vibration and improved surface finish. This is especially important in high-speed applications, where even the smallest imperfections can affect the quality of the final product.

Using HSK-A spindles in machine shops

The implementation of HSK-A spindles in machine shops requires a thorough understanding of their characteristics and capabilities. It is essential that operators are properly trained to fully exploit the advantages offered by these tools. Correct installation and regular maintenance are essential to ensure optimal performance and long spindle life. In addition, it is important to select the appropriate HSK-A spindle according to the specific needs of the application, taking into account factors such as rotation speed, type of material to be machined and required tolerances.

Frequently asked questions about HSK-A spindles DIN 69893A

1. What is the difference between HSK-A spindles and other spindle types?

HSK-A spindles offer a more rigid and stable connection due to their hollow-shank design, which reduces vibration and improves accuracy compared to conventional spindles.

2. How is the maintenance of HSK-A spindles carried out?

Maintenance of HSK-A spindles includes regular cleaning, inspection of contact surfaces and checking tolerances to ensure optimum performance.

3. What are the ideal applications for HSK-A spindles?

HSK-A spindles are ideal for high-speed, high-precision applications such as milling, drilling and turning on CNC machines.

4. Are HSK-A spindles compatible with all machine tools?

HSK-A spindles are designed to be compatible with machine tools that support DIN 69893A, but it is important to check compatibility with the machine manufacturer.

5. What are the economic advantages of using HSK-A spindles?

The use of HSK-A spindles can lead to greater production efficiency, reducing machining time and improving the quality of the end product, resulting in savings in operating costs.

Conclusions

HSK-A DIN 69893A spindles are an advanced solution for machine shops looking to improve the precision and efficiency of their operations. Thanks to their innovative design and superior performance, these spindles offer numerous advantages over traditional models. However, to realise their full potential, it is essential to understand their features, ideal applications and maintenance practices. With the right training and attention to detail, HSK-A spindles can become a key element in successful machining operations.

Read More Read Less