< Chemical, adhesives and sealants Lubrication accessories

Lubrication accessories are a key element in the proper functioning of machine shops. These often underestimated tools play a crucial role in ensuring the efficiency and longevity of machines and systems. In this in-depth look, we will explore in detail what lubrication accessories are, what they are used for, how they are used, the advantages of using them and answer the most frequently asked questions on this topic.

The importance of lubrication accessories in machine shops

In the context of machine shops, lubrication is an essential process that reduces friction between moving machine parts, preventing wear and overheating. Lubrication accessories, such as pumps, nozzles, reservoirs and distributors, are designed to optimise this process, ensuring that the lubricant is applied evenly and precisely. Without proper lubrication, machines can suffer significant damage, leading to costly downtime and repairs.

Types of lubrication accessories

There are different types of lubrication accessories, each with specific applications and advantages. Among the most common are:

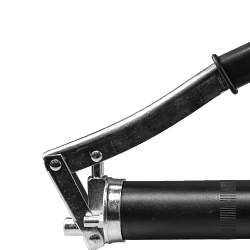

- Lubrication pumps: used to transfer lubricant from the reservoir to the machine parts that need lubrication. They can be manual or automatic, depending on the workshop's needs.

- Nozzles and distributors: they allow lubricant to be applied in a precise and controlled manner, reducing waste and ensuring uniform coverage.

- Tanks and containers: designed to store lubricant safely, preventing contamination and leakage.

- Lubrication filters: essential for keeping lubricant clean and free of impurities that could damage machines.

How to choose the right lubrication accessories

The choice of lubrication accessories depends on several factors, including the type of machines used, the type of lubricant used and the specific operational needs of the workshop. It is important to consider the compatibility of the accessories with existing systems and ease of maintenance. In addition, energy efficiency and sustainability have become increasingly important criteria when selecting lubrication accessories.

Benefits of using quality lubrication accessories

The adoption of high-quality lubrication accessories offers numerous advantages, including:

- Reduced wear and tear: effective lubrication reduces friction between moving parts, extending the service life of machines.

- Improved operating efficiency: well-lubricated machines run more smoothly and with fewer interruptions, increasing workshop productivity.

- Maintenance cost savings: preventing wear and tear and breakdowns reduces the need for costly repairs and replacements.

- Operational safety: proper lubrication reduces the risk of overheating and sudden breakdowns, improving safety at work.

Frequently asked questions about lubrication accessories

1. What is the ideal frequency for machine lubrication?

The frequency of lubrication depends on the type of machine and operating conditions. It is advisable to follow the manufacturer's recommendations and monitor the condition of the lubricant regularly.

2. Can the same lubricant be used for all machines?

No, it is important to use the specific lubricant recommended for each type of machine, as different lubricants have different properties and viscosities.

3. How can the effectiveness of lubrication be checked?

The effectiveness of lubrication can be monitored by analysing the lubricant, which allows contamination or degradation of the product to be detected.

4. What are the signs of inadequate lubrication?

Abnormal noises, overheating and excessive part wear are signs of inadequate lubrication.

5. Is it necessary to train personnel in the use of lubrication accessories?

Yes, proper training of personnel is essential to ensure correct and safe use of lubrication accessories.

Conclusions

Lubrication accessories are indispensable tools for the proper functioning of machine shops. Investing in quality accessories and ensuring regular maintenance can lead to significant improvements in operational efficiency, safety and cost reduction. With a thorough understanding of their functions and benefits, garages can optimise their lubrication processes and ensure the longevity of their equipment.

Read More Read Less