< Abrasives Polishing felt

In the world of machine shops, efficiency and precision are key elements in guaranteeing high-quality results. Among the indispensable tools for achieving these goals, polishing felts occupy a prominent place. These often underestimated materials play a crucial role in the finishing process of metal surfaces, helping to achieve smooth and shiny surfaces. In this in-depth look, we will explore in detail what polishing felts are, how they are used, the benefits they offer and answer some of the most frequently asked questions on this topic.

Understanding Polishing Felts

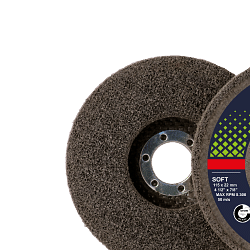

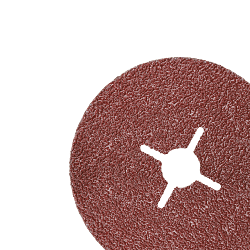

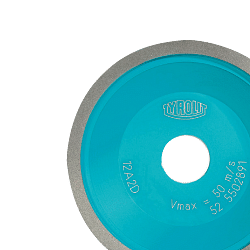

Polishing felts are abrasive materials used for finishing and polishing metal and other surfaces. Made mainly of compressed wool or synthetic fibres, these felts are designed to be mounted on rotary tools, such as grinders or drills, and used in combination with abrasive pastes or polishing compounds. Their soft but strong structure allows surface imperfections, scratches and oxidation to be removed, leaving a smooth and shiny finish.

Applications and use of polishing felts

Polishing felts find applications in a wide range of industries, including automotive, aerospace, jewellery and toolmaking. In machine shops, they are particularly appreciated for their ability to improve the aesthetics and functionality of metal components. The use of polishing felts is relatively simple: once the felt is mounted on the rotating tool, a small amount of polishing compound is applied to the surface to be treated. Next, you proceed with uniform and controlled movements, applying light pressure to avoid damaging the underlying material.

Advantages of polishing felts

The use of polishing felts offers numerous advantages, including:

1. High-quality finish: Polishing felts are able to remove micro-scratches and imperfections, ensuring a smooth and shiny surface.

2. Versatility: They can be used on a wide range of materials, including metals, glass, plastics and precious stones.

3. Efficiency: Thanks to their ability to work quickly and accurately, polishing felts reduce processing time and improve productivity.

4. Durability: The high-quality felts are wear-resistant and can be used repeatedly without losing their abrasive properties.

5. Safety: Unlike other polishing methods, felts reduce the risk of overheating and damage to the treated material.

Frequently asked questions about polishing felts

1. What is the difference between natural and synthetic felts?

Natural felts, made of wool, offer a higher absorption capacity for polishing compounds and are ideal for applications requiring a high-gloss finish. Synthetic felts, on the other hand, are more wear-resistant and can be used on harder materials.

2. How to choose the right polishing felt?

The choice of felt depends on the type of material to be treated and the desired level of finish. It is important to consider the hardness of the felt, its density and compatibility with the polishing compounds used.

3. Can polishing felts be used on painted surfaces?

Yes, polishing felts can be used on painted surfaces, but it is essential to use specific polishing compounds to avoid damaging the paint.

4. How can polishing felts be kept in good condition?

To ensure the longevity of the felts, it is advisable to clean them regularly to remove residues of polishing compounds and dust. Furthermore, it is important to store them in a dry environment and away from heat sources.

Conclusions

Polishing felts are an essential tool for machine shops wishing to achieve high quality surfaces. Their versatility, efficiency and ability to ensure a flawless finish make them an ideal choice for a wide range of industrial applications. Understanding the characteristics and how to use polishing felts is crucial to fully exploit their benefits and improve the quality of finished products. With proper selection and maintenance, polishing felts can become a valuable ally in the metalworking process and beyond.

Read More Read Less