< Abrasives Flap discs

Flap discs are an essential component in the panorama of machine shops, offering advanced solutions for metalworking. These tools, known for their efficiency and versatility, are designed to optimise finishing and honing processes, guaranteeing high quality results. In this in-depth look, we will explore in detail what flap discs are, how they are used, the advantages they offer and answer the most frequently asked questions that arise in the industrial context.

Understanding flap discs

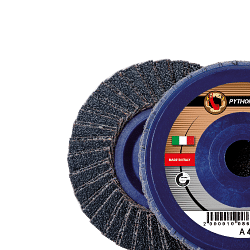

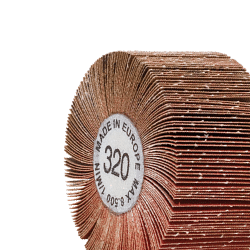

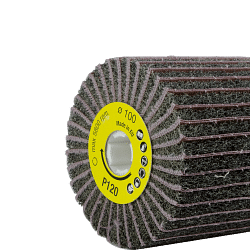

Flap discs are abrasive tools consisting of a series of overlapping flaps, usually made of abrasive material such as aluminium oxide or silicon carbide. These flaps are arranged in a fan shape around a central backing, usually made of fibreglass or reinforced plastic, which gives the disc a strong and durable structure. The flap configuration allows an even distribution of pressure during use, improving the efficiency of the abrasion process.

Applications and use of flap discs

Flap discs are used in a wide range of industrial applications due to their ability to adapt to different surfaces and materials. They are particularly popular in machine shops for deburring, sanding, rust and paint removal, as well as for surface preparation prior to painting. Their versatility makes them suitable for working on steel, stainless steel, aluminium and other metals, as well as composite materials and alloys.

The use of flap discs is relatively simple, but requires care to ensure optimal results and operational safety. It is essential to select the appropriate disc according to the material to be machined and the desired finish. In addition, it is important to mount the disc correctly on the rotating tool, ensuring that it is well secured to avoid excessive vibration or misalignment during use.

Advantages of flap discs

One of the main advantages of flap discs is their ability to provide a uniform, high-quality finish. The fan-shaped arrangement of the flap discs allows an even distribution of pressure, reducing the risk of unwanted scratches or marks on the machined surface. In addition, flap discs tend to last longer than conventional abrasive discs due to their structure, which allows for gradual consumption of the abrasive material.

Another positive aspect is the reduction in machining time. Flap discs are designed to remove material quickly and efficiently, allowing operators to complete finishing operations in a shorter time. This translates into increased productivity and reduced operating costs for machine shops.

Frequently asked questions about flap discs

1. What is the difference between a flap disc and a conventional abrasive disc?

Flap discs offer longer life and a smoother finish than traditional abrasive discs. Their flap structure allows a more even distribution of pressure, reducing the risk of damaging the machined surface.

2. How do I choose the right flap disc for my project?

The choice of flap disc depends on the material to be machined and the type of finish desired. It is important to consider the abrasive grain, disc diameter and type of backing to ensure optimum results.

3. Can flap discs be used on non-metallic materials?

Yes, flap discs are also suitable for working on non-metallic materials such as wood, plastic and composite materials. However, it is important to select the appropriate type of abrasive to avoid damage to the material.

4. What safety precautions should be taken when using flap discs?

It is essential to wear personal protective equipment such as safety glasses, gloves and hearing protection. Furthermore, it is important to make sure that the disc is mounted correctly and that the rotating tool is in good condition.

5. How long do flap discs last?

The lifetime of flap discs depends on the intensity and frequency of use, as well as the type of material being processed. In general, flap discs tend to last longer than conventional abrasive discs due to their robust construction.

Conclusions

Flap discs are an advanced and versatile solution for machine shops, offering numerous advantages in terms of efficiency, finish quality and durability. Their ability to adapt to different applications and materials makes them an indispensable tool for anyone working in the metalworking industry. With proper selection and use, flap discs can contribute significantly to improving productivity and reducing operating costs, while guaranteeing high quality results.

Read More Read Less