< Abrasives Abrasive stones

Abrasive stones are a key element in the landscape of machine shops, a sector where precision and efficiency are paramount. These tools, although often overlooked, play a crucial role in ensuring the quality and finish of machined products. In this in-depth look, we will explore in detail what abrasive stones are, what they are used for, how they are used, the advantages of using them and answer some of the most frequently asked questions on this topic.

Understanding abrasive stones

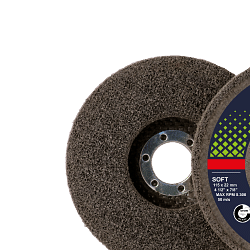

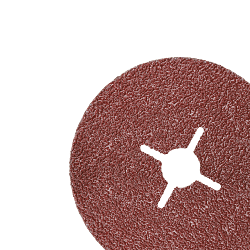

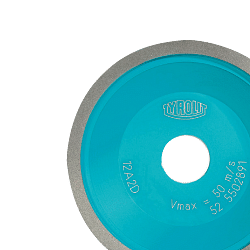

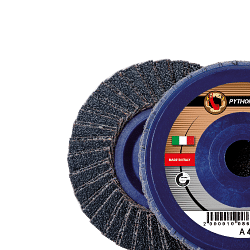

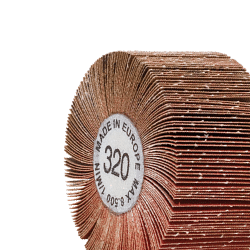

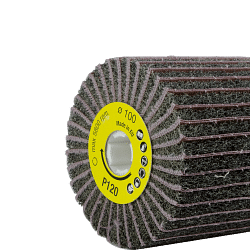

Abrasive stones are tools used for processing metal and non-metal surfaces. They are composed of abrasive materials bonded together to form a strong, solid structure. These abrasive materials can vary, but the most common include aluminium oxide, silicon carbide and diamond. The choice of abrasive material depends on the type of work and the material to be processed.

Main functions of abrasive stones

Abrasive stones are mainly used for grinding, honing and polishing surfaces. Grinding is a machining process that removes material from a surface to improve its finish or to obtain precise dimensions. Honing, on the other hand, is a more delicate process that aims to remove small imperfections and prepare the surface for further treatment. Finally, polishing is the final process that gives the surface a smooth, shiny appearance.

Use of abrasive stones in machine shops

In machine shops, abrasive stones are used in a variety of applications. They are essential for tool maintenance, surface preparation before painting, and finishing mechanical components. The correct use of abrasive stones requires a thorough understanding of their characteristics, such as grit, hardness and structure. Grit refers to the size of the abrasive particles, while hardness indicates the stone's resistance to wear. Structure, finally, refers to the arrangement of the abrasive particles within the stone.

Advantages of using abrasive stones

The use of abrasive stones offers numerous advantages. Firstly, they enable extremely smooth and precise surfaces, which are essential for the proper functioning of many mechanical components. In addition, abrasive stones can extend the life of tools, reducing the need for frequent replacement. This translates into significant cost savings for machine shops. Finally, the use of abrasive stones can improve the overall efficiency of the production process, reducing machining time and improving the quality of the end product.

Frequently asked questions about abrasive stones

1. What is the difference between an abrasive stone and a grinding wheel?

Abrasive stones and grinding wheels are both used for surface processing, but differ in their structure and application. Grinding stones are generally larger and used for grinding large surfaces, while honing stones are smaller and suitable for precision work.

2. How do I choose the right honing stone for a specific application?

The choice of abrasive stone depends on the material to be processed and the type of finish desired. It is important to consider grit, hardness and abrasive material for best results.

3. Can abrasive stones be used on non-metallic materials?

Yes, abrasive stones can be used on a variety of non-metallic materials, such as plastic, ceramic and glass. However, it is important to choose the right type of abrasive stone for the specific material to avoid damage.

4. What safety precautions should be taken when using abrasive stones?

It is essential to wear personal protective equipment, such as safety goggles and gloves, to protect yourself from chips and abrasive dust. Furthermore, it is important to follow the manufacturer's instructions for the correct use of abrasive stones.

5. How do I maintain an abrasive stone in good condition?

Maintenance of honing stones includes regular cleaning to remove material residue and inspection for damage or wear. It is important to store abrasive stones in a dry environment to prevent corrosion.

Conclusion

Abrasive stones are indispensable tools in machine shops, offering precision and quality in surface processing. Understanding their characteristics and use is essential to maximise the benefits they can offer. With the right knowledge and attention, abrasive stones can significantly improve the efficiency and quality of production processes, contributing to the overall success of the workshop.

Read More Read Less