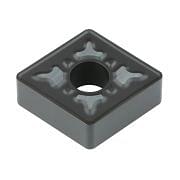

Negative and positive turning inserts

Negative and positive turning inserts are essential tools in machine shops, particularly appreciated for their ability to optimise metalworking processes. These inserts, available in different variants, play a crucial role in the precision and efficiency of turning, one of the most widely used techniques in industrial production.

Negative turning inserts are characterised by a robust geometry that makes them ideal for heavy machining. Their symmetrical shape allows both sides to be used, thus extending tool life and reducing operating costs. These inserts are particularly effective when turning hard materials such as alloy steels and stainless steels due to their ability to withstand high thermal and mechanical stresses. The most common variants include chip-breaker inserts, which facilitate chip management during the machining process, improving the surface finish of the workpiece.

On the other hand, positive turning inserts are known for their ease of use and versatility. With a positive rake angle, they offer a softer cut and reduced cutting force, making them ideal for machining softer materials such as aluminium and non-ferrous alloys. These inserts are also particularly suitable for finishing operations, where high precision and optimum surface quality are required. The most common variants include inserts with special coatings that improve wear resistance and extend tool life.

In a modern machine shop, the choice between negative and positive turning inserts depends on the specific machining requirements. For example, for operations requiring high stock removal, negative inserts are often preferred for their durability and strength. Conversely, for precision work on soft materials, positive inserts are the ideal choice.

In addition to selecting the appropriate insert, it is also crucial to consider other factors such as cutting speed, feed rate and depth of cut. The correct combination of these parameters, together with the choice of insert, can significantly improve workshop efficiency and productivity. Investing in high quality inserts and proper staff training can result in reduced downtime, improved quality of the finished product, and ultimately, increased competitiveness in the market.