Free shipping in 24h from 200€

Catalogues

Customer service

How can we help you?

- Faq

- Customer service

+31(0)85-0471271

- Supporting big orders

02.38298620

-

info@linkindustrialtools.nl

- Request assistance with form

Or contact us with the chat in the lower right corner

- All products

Solid cutting tools

Solid cutting tools Turning tools

Turning tools Thread tools

Thread tools Thread tools

Thread tools- All products

- Thread inserts

Milling cutters

Milling cutters Drilling tools

Drilling tools Drilling tools

Drilling tools- All products

- Indexable drill bits

- Indexable drill heads

Clamping systems

Clamping systems Clamping systems

Clamping systems- All products

- Spindles SK DIN 69871

- Chucks MAS 403 BT

- Chucks HSK-A DIN 69893A

- Chucks DIN 2080 and cylindrical

- Spring collects for locking and chucks

- Angle heads

- Driven tool holders

- Self centering chucks

- Magnetic plates

- Clamping Jaws. Live centers, face drivers

- Various accessories for clamping

- Zero-point clamping systems

Measuring and precision tools

Measuring and precision tools Measuring and precision tools

Measuring and precision tools- All products

- Digital calipers with readings to 0.01

- Analogue calipers

- Digital micrometers

- Analogue micrometers

- Bore gauges

- Snap gauges

- Digital gauges

- Analogue gauges

- Touch probes

- Zero setters and edge finders

- Inspection plates

- Altimeters

- Height gauges

- Squares and levels

- Threaded rings

- Gauge blocks

- Calibrated tapes and thickness gauges

- Digital and analogue hardness testers

- Roughness testers

- Microscopes, lenses and visors

- Digital thermo-hygrometer to measure moisture

- Reset benches

- Optical profile projector

- Professional, digital dynamometers

- Laboratory scales

- Digital amperometric pliers

- Thickness and adhesion gauges

Hand tools

Hand tools Hand tools

Hand tools- All products

- Combination wrenches

- Spanners

- Hook wrenches

- Tubular wrenches

- Hexagon keys

- Torx wrench

- Socket wrenches

- Screwdrivers

- Torque wrenches

- Torque screwdriver

- Inserts and bits for screw drivers

- Tool trolleys

- Workshop pliers

- Wire strippers

- Cable strippers

- Cutting nippers

- Professional scissors

- Nippers

- Professional shears

- American or Swedish pipe wrench

- Adjustable wrench

- Pipe tools

- Pipe cutter for plumber

- Cutter

- Hacksaws

- Deburring tools

- Chisels

- Hammers and mallets

- Mechanical and conical pullers

- Clamps

- Tap wrenches and die stocks

- Riveters

- Flexometers

- Tape measures

- Markers

- Flat squares and rulers

- Professional dividers

- Professional protractors

- Brushes

- Lubricators and spray nozzles

- T-wrenches

- Reversible ratchets

Abrasives

Abrasives Abrasives

Abrasives- All products

- Cutting discs

- Deburring grinding wheel

- Flap discs

- Fabric discs for surface treatment

- Abrasive fibre discs with Velcro

- Abrasive cloth in rolls, sheets and bands

- Flap wheels with pin and abrasive wheel with hole

- Abrasive wheels for buffing machines

- Abrasive spiral bands

- Abrasive brushes

- Flexible sanders

- Mounted grinding discs

- Polishing felt

- Solid carbide rotary cutters

- HSS rotary cutters

- Abrasive wheels for sharpening and grinding

- Diamond needle files

- Grinding stone

- Diamond paste

- Abrasive stones

- Files and rasps

- Diamond files

- Grinders and polishing equipment

Lubricants for machine tools

Lubricants for machine tools Lubricants for machine tools

Lubricants for machine tools- All products

- Water-miscible coolants

- Neat cutting oil

- Minimal lubrication systems

- Oil for guides and slides

- Drums of hydraulic oil fluid

- Anti-freeze for machine tools

- Air coolers

- Oil separator

- Powders and absorbents for oil

- Aspirators for oil mist

- Accessories for cooling lubricants

- Metal and mould protectors

- Grease and paste

Chemical, adhesives and sealants

Chemical, adhesives and sealants Chemical, adhesives and sealants

Chemical, adhesives and sealants- All products

- Acrylic, cyanoacrylate and epoxy adhesives

- Guns and silicon sealant

- Threadlocker

- Sealants and retainers

- Release agents, lubricants and anti-seize

- Zinc spray and polishes

- Lubrication accessories

- Protections for maintenance

- Industrial Cleansing

- Handwash

- Industrial cloths and rags

- Welding machines

- Electrodes

- Clamps, shields and welding masks

- Antispatter

Safety equipment

Safety equipment Pneumatics

Pneumatics Lifting systems

Lifting systems Workshop equipment

Workshop equipment Workshop equipment

Workshop equipment- All products

- Column and bench drills

- Lathe and accessories

- Band saws

- Cut-off machines

- Bench grinders

- Power tools

- Spare parts and accessories for Power Tools

- Saws and hole cutters: wood, metal and plasterboard

- Tapered cutters for sheet metal

- Industrial aspirators

- Fume aspirators

- Bench vices

- Technical lamps

- LED torches

- Industrial cable winders

- Trolley wheels

- Quick clamps

- Threaded inserts

- Control knobs

- Packaging accessories and material

- Belt sanders

- Electric tapping machines

Furnishings and storage

Furnishings and storage Furnishings and storage

Furnishings and storage- All products

- Work benches

- Swivel chairs for office use

- Drawer units for workshops

- Industrial cabinets for warehouses and workshops

- Tool cabinets

- Security cabinets

- Changing room cabinets

- Containers for small metal parts

- Scrap holders

- Workshop trolleys

- Spill pallets for drum storage

- Shelves for warehouses and offices

- Cantilever shelving

- Aluminium ladders

- Modular plinths

- Units and cabinets for waste recycling

Brand

BrandPromotions

Bestseller

Bestseller- Catalogues

-

Catalogues

Customer service

How can we help you?

- Faq

- Customer service

+31(0)85-0471271

- Supporting big orders

02.38298620

-

info@linkindustrialtools.nl

- Request assistance with form

Or contact us with the chat in the lower right corner

SCHÜSSLER

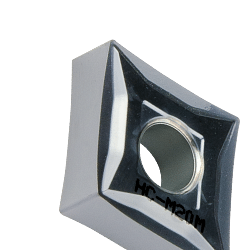

SCHÜSSLER: Precision Chucks for Mechanical Machining

SCHÜSSLER is a brand specialising in the production of precision chucks for machine tools. With a focus on quality, reliability and technological innovation, SCHÜSSLER products guarantee high performance for tool clamping in sectors such as the mechanical, aerospace and automotive industries.

Why choose SCHÜSSLER chucks?

- Precision and Stability – Safe and repeatable clamping for high quality machining.

- Reliability and Durability – Resistant materials and advanced treatments for a long operating life.

- Technological Innovation – Design studied to reduce vibrations and guarantee maximum control of the piece.

- Wide Range of Products – Spindles for milling, turning, drilling and grinding.

- Universal Compatibility – Solutions suitable for different machine tools and applications.

SCHÜSSLER Product Range

1. Milling Spindles

Designed to ensure secure clamping and reduce vibration during high-speed machining.

- ER collet chucks – High precision for precision milling and general machining.

- HSK chucks – Rigid connection for high speed milling machines with high stability.

- BT and SK chucks – Perfect for CNC machining centre applications.

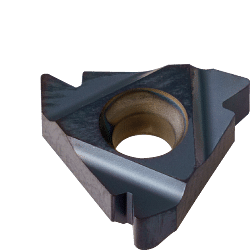

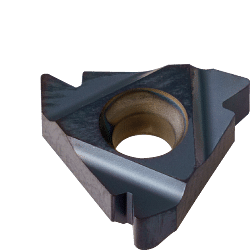

2. Chucks for turning

Clamping tools designed to ensure precision and rigidity in turning operations.

- Self-centring chucks – Ideal for workpieces of varying dimensions with uniform clamping.

- Hydraulic chucks – Guarantee high clamping force and reduced vibration.

- Elastic expansion chucks – Perfect for machining operations that require high concentricity.

3. Drilling and Grinding Chucks

Optimised to guarantee maximum precision and stability in drilling and grinding operations.

- Rack and pinion chucks – Ideal for deep drilling and high performance.

- Quick-clamping chucks – Fast tool change to improve operational efficiency.

- Precision grinding chucks – Designed for machining with tight tolerances.

4. Accessories and spare parts for chucks

A wide range of support components to optimise spindle performance.

- Collet chucks – Available in different sizes to suit every need.

- Collet wrenches – Ergonomic tools for quick and safe tool changes.

- Anti-vibration elements – Reduction of oscillations for more precise machining.

Industrial Applications

SCHÜSSLER spindles are used in various industrial sectors:

- Mechanical Industry – For precision machining on steels, alloys and advanced materials.

- Aerospace – For the production of highly complex components with tight tolerances.

- Automotive – For milling, turning and drilling of mechanical parts and engine components.

- Energy sector – For machining materials used in turbines and industrial plants.

- Moulding and mould production – For high-precision machining in complex production environments.

Conclusion

Choosing SCHÜSSLER means relying on a brand specialised in precision clamping technology. With a complete range of chucks for milling, turning, drilling and grinding, SCHÜSSLER guarantees reliability, durability and maximum precision, meeting the needs of the most advanced industries.